Machining centers, unlike other CNC machines, combine many functions. The reason for using the term “center” is attributed to the fact that it encompasses many features in one place. A Machining Center can be horizontal, vertical, and universal type. Because of Computer-controlled tools in a Machining Center, unlike other standard CNC machines, complete much more complex operations without reflecting complexity to the CNC operator. These CNC machines are generally famous for being more robust, rigid, and efficient than other machines. At the same time, they are more expensive due to the advanced functions they provide. Machining centers provide advanced Automatic Tool Changers, Automatic Pallet Changers, chips, and coolant management.

This article explains everything you need to know about Machining centers. We will deep-dive into types of machining centers, their features, what makes them a good choice over others, why they are different than other CNC machines, etc.

- What is a Machining Center?

- How Does a Machining Center Work?

- Types of Machining Centers?

- Components of a Machining Center

- Practical Applications of Machining Centers

- Investing in a Machining Center: Cost Implications

- FQA for HMC, VMC, UMC Machines

- What is meant by machining center?

- What is the difference between CNC and machining center?

- What is the function of machining center?

- What are the two basic types of machining centers?

- Is a machining center a mill?

- What is the characteristic of machining Centre?

- What is VMC in CNC?

- What is difference between CNC VMC and HMC?

- What is HMC in CNC?

- What are the applications of HMC machine?

- What is HMC working principle?

- Conclusion

What is a Machining Center?

A Machining Center is a convenient CNC machine with the ability to perform many standard and advanced machining operations such as hole drilling, milling, boring, and tapping. It is an all-in-one solution, along with the feature of tool and pallet changing functions.

How Does a Machining Center Work?

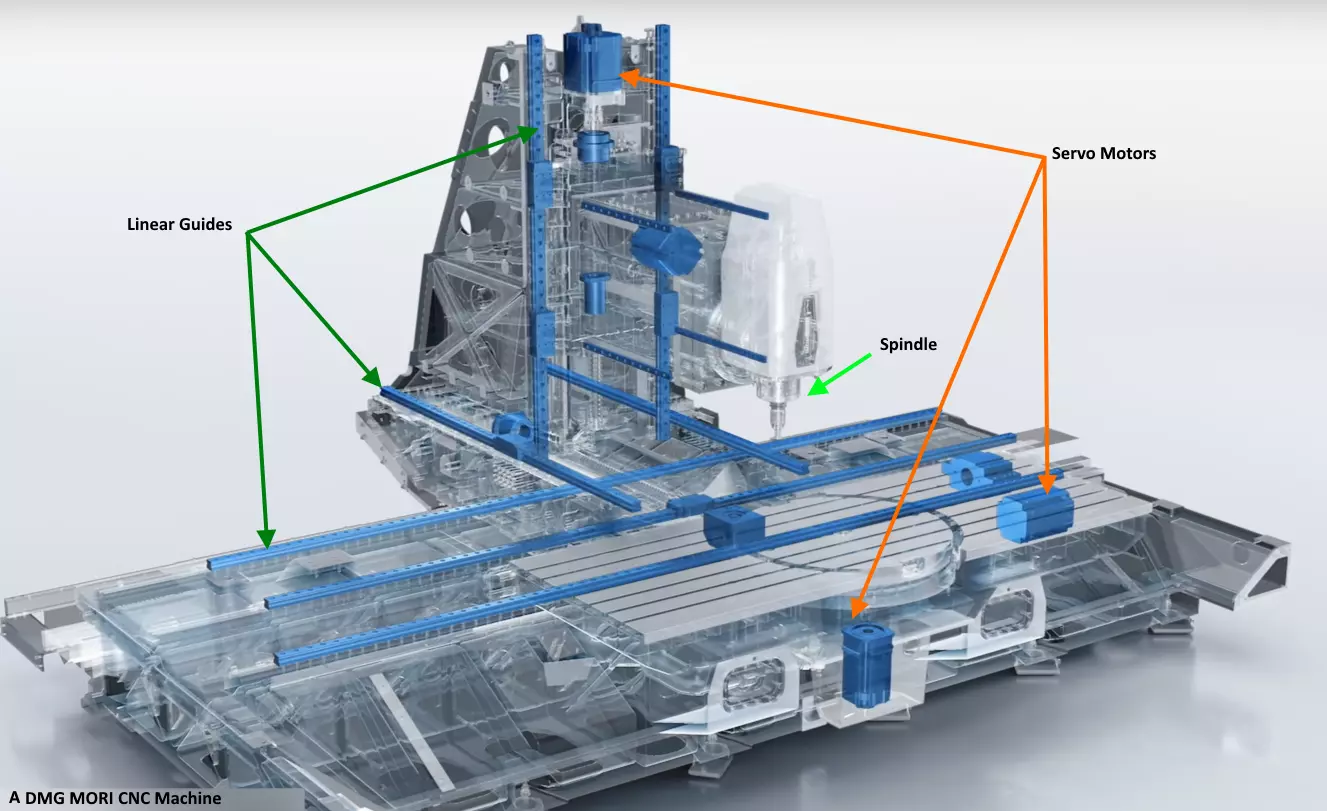

Machining Centers work using computerized control systems, just like other CNC machines. They have servo motors working alongside drivers, and there’s also a PLC (programming logic controller) included. The PLC manages various tasks in the system, such as changing tools, swapping pallets, controlling probing cycles, and controlling the chip conveyor. The program, which is in G-Code format, is read by the controller, and it oversees the real-time control of the X, Y, and Z axes.

Types of Machining Centers?

CNC Machining Centers are best known for 3 types of machines. They are generally named by the position of the spindle. They are Horizontal Machining Center, Vertical Machining Center–VMC, and UMC.

If you wondering about a comprehensive machine provider list for machining centers you can check the HAAS CNC web page.

Horizontal Machining Center:

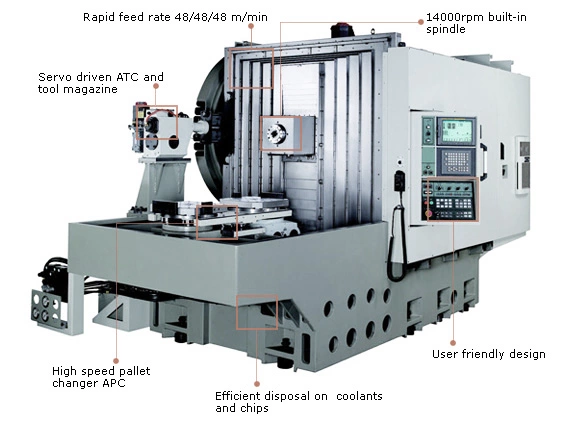

Horizontal Machining Centers are large and heavy machines. The term “horizontal” comes from the positioning of the spindle in a horizontal orientation. One of the most important features of this machining center is the ability to automatically change palettes (APC) which are also known as tables. Thanks to work-holding towers called Tomb-Stones, all four sides of a pallet can be machined. Moreover, while the machine is running, a tombstone on the standby pallet is set up for machining new parts. This leads to significant time savings. This machine has a very large cutting tool storage capacity in Automatic Tool Changer (ATC). Pockets in tool magazines can vary between 10 to 150 tools.

Another well-known feature is its ability to perform deep-hole boring operations quite easily due to its horizontal spindle orientation. By adding extensions to the end of the horizontal spindle, it becomes convenient to reach the deep features of the workpiece. It has a very wide range of boring bars and holders. Since the workpiece and spindle are positioned horizontally, the chips produced during cutting easily fall onto the chip conveyor due to the force of gravity. This enables the maximization of the material removal rate(MMR). It is often used by automotive part manufacturers, the aerospace industry, and the steel construction industry. Its structural design is inspired by the conventional Horizontal Boring Machines. CNC machine`s coordinate systems and motion axes are X, and Y, Z.

Vertical Machining Center:

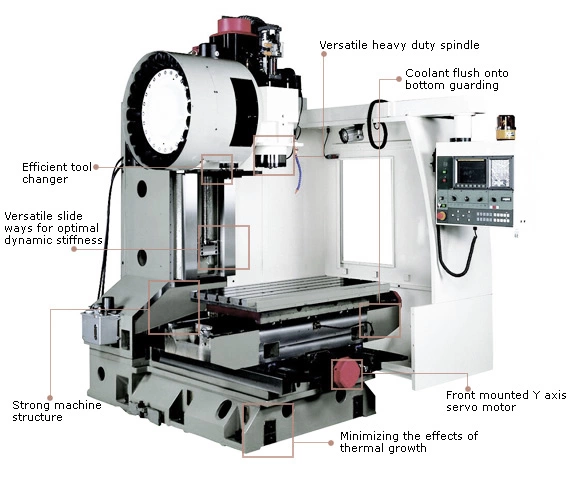

Vertical machining centers are known for being more compact, although there are larger bridge-style versions as well. The term “vertical” refers to the upright positioning of the spindle. Tool magazines are smaller, but it’s important to note that due to their compact structures, more advanced features can easily be added.

Operations such as engraving, hole drilling, 3D surface machining, tapping, and more can be easily carried out on this machine. It’s commonly used by mold manufacturers and machine component producers. Its widespread presence in almost every CNC workshop is notable. The simple design is inspired by standard milling machines. Work-holding can be done with easy tools like step clamps, screws, and vises.

Those machines are often called 3-axis machines similar to HMC which have 3-axis movement coordinate systems X, Y, and Z. Automatic Tool Changers(ATC) are almost standard with VMC and they can hold 30-50 tools on tool magazines. VMC machines can have APC(automatic palette changers) but because of the vertical structure of the machine, it is not common due to big table sizes.

Haas and Victor-Taichung is one of the famous VMC manufacturers

Universal Machining Center:

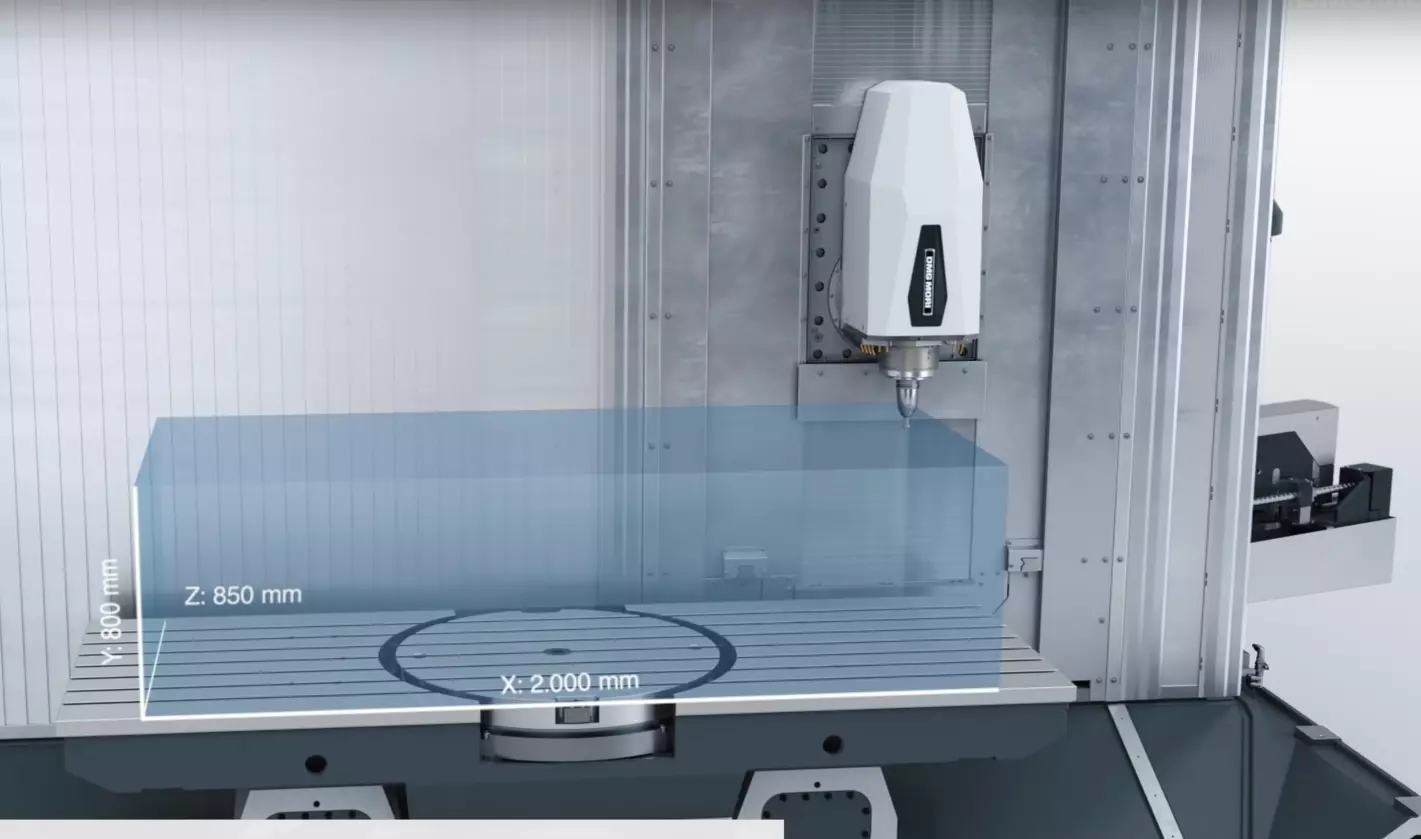

Universal Machining Centers are essentially a system composed of three axes, and they are created by adding the extra two axes to a standard CNC machine. The purpose of these machines is to reduce setup time for parts and enable the processing of complex components more swiftly. You can think of it this way: when working on a part with a vertical or horizontal machining center, you can’t access its other surfaces without removing the part from the machine and repositioning it. To minimize this process, universal machining centers are equipped with two additional axes that allow effective access and processing of the other sides of the part.

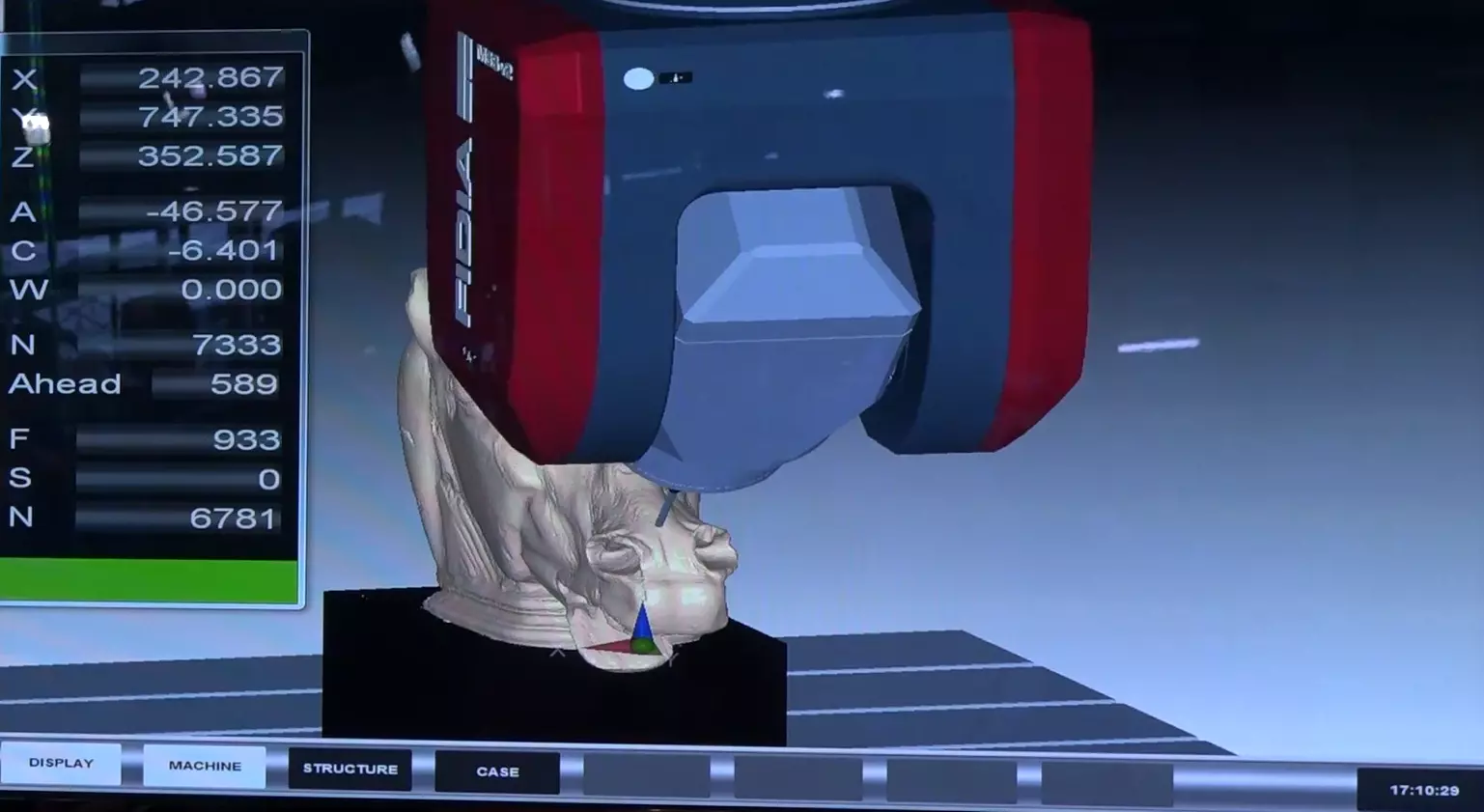

In this way, you can work on all five sides of the part without removing it from the machine. These extra two axes(A, B) can also move with high precision like the other three axes(X, Y, Z), especially for drilling holes and performing machining operations on angled surfaces. Additionally, they can control all five axes simultaneously. That’s why you might often hear these machines referred to as multi-axis machines. However, the most common term you’ll come across is five-axis CNC machines. If you wonder about the range of UMC machines you can check from FIDIA which is a large-size machine manufacturer.

What makes UMC very different than VMC and HMC?

Universal machining centers are produced in various different ways compared to horizontal and vertical machining centers. For instance, there’s a type of CNC machine with a cradle-like table, and this is a five-axis machine. Another variation is essentially horizontal in operation but features a cradle-like moving table as well. These machines, with their advanced capabilities, bring various challenges and complexities to our workplaces. One of the most significant challenges is the need for custom-designed CAM software. Regular CAM software is built around three-axis programming as the standard. Therefore, without additional cost, you can start using a three-axis CNC machine by employing any standard CAM software.

This might be a horizontal machining center or even a dual machining center. Since it’s fundamentally a three-axis machine, programming for the X, Y, and Z axes can be straightforwardly accessed through standard programming methods. However, when it comes to universal machining centers, things get quite intricate. This is because each machine has different dimensions rotational axes, and tilt angle configurations. Aspects like the orientation of rotation axes, inclination axes, max/min. tilt angle and spindle configuration make programming these machines more challenging. Nevertheless, modern software companies have found solutions and offer us the ability to draw all machines accurately and facilitate programming in these machines. But all these advantages come at a considerable cost. Because there’s no standard system, software developed for programming universal machining centers(UMC) is custom-made and solely used for programming these centers. This is due to the fact that these systems need to include features like advanced collision control and postprocessors.

When there are elements like rotating tables and spindles involved, the risk of collisions is significantly higher, and to minimize this risk in such machines, a sophisticated cutting simulation/verification system is required. As I said before Software companies excel in providing this, but it often comes at a premium price. Hence, universal machining centers are more expensive than their horizontal and vertical counterparts. However, due to the benefits, conveniences, and time savings they offer, many companies prefer these centers today.

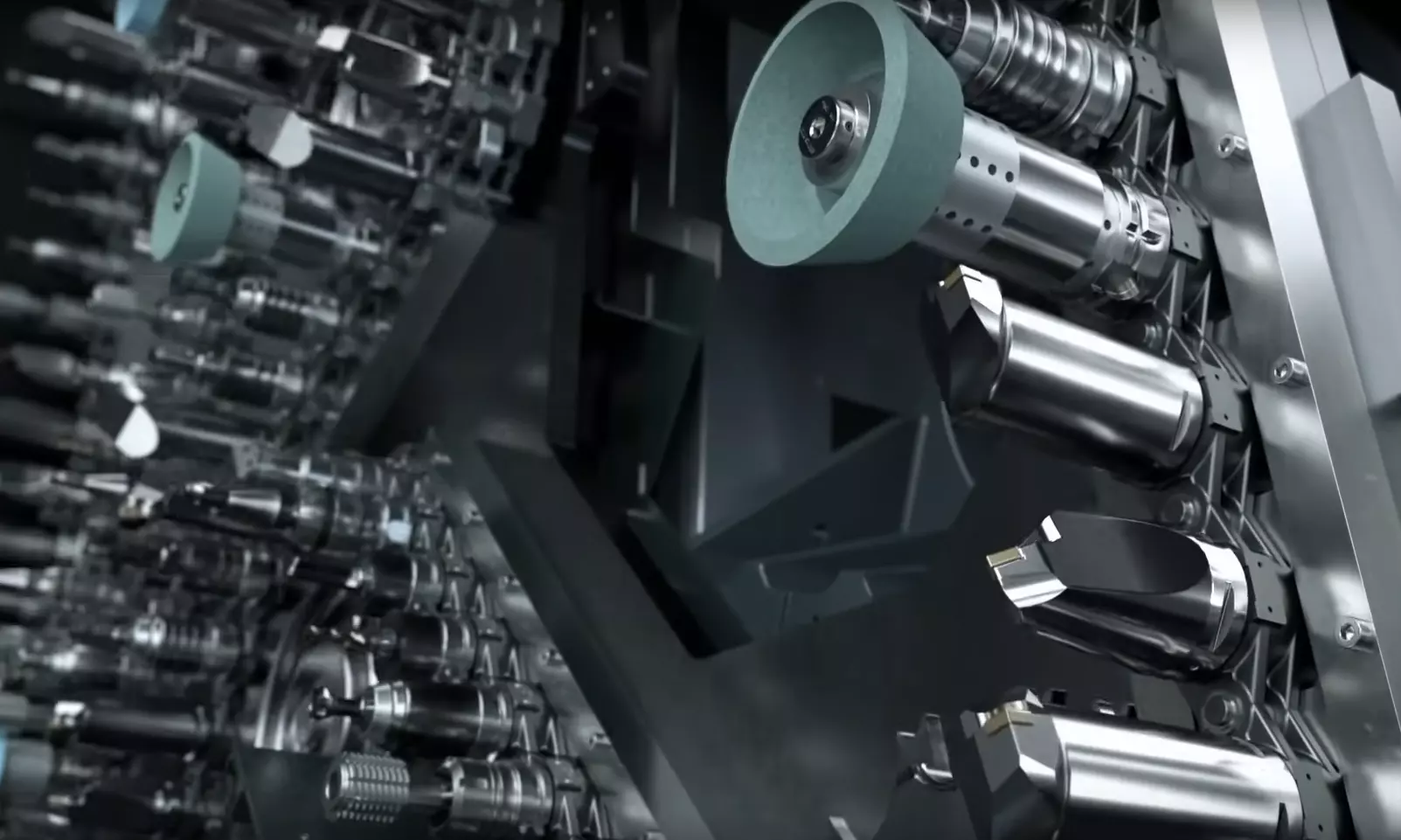

Components of a Machining Center

We’ve looked at the different types of machining centers. Now, let’s focus on the key component of machining centers:

1-Spindle:

The spindle is a crucial and precise component in all machining centers, including both manual and automatic CNC machines. In the past, spindles were controlled by servo motors or DC motors and were driven externally by a belt. However, these systems have largely disappeared in new machining centers. For instance, modern spindles contain motor windings within them. This collaboration allows the spindle to have its own servo motor inside its housing and operate smoothly with specialized bearings. One of the most significant benefits of this system is reduced vibration. Since the motor is integrated within and not externally attached, issues related to space are eliminated, leading to smaller machine dimensions. This, in turn, provides access to areas on the workpiece that were previously difficult to reach due to the elimination of space constraints.

Moreover, the built-in servo motor allows for extremely high precision and angular control of the spindle. With precise and fine control over motion, a wide variety of operations can be carried out on different surfaces with ease using these spindles.

2-Feed Mechanism:

Feeding mechanisms in a machining center are very crucial. One of the most renowned feeding systems is the ball-screw and ball-nut system, which provides high-resolution positioning. As an alternative to this system, linear servo motors have been developed in recent times. Given the advanced nature of machining centers today, many new machining centers employ linear servo motors. Thanks to these motors, the system accomplishes both the functions of a linear guide system and motor positioning without the need for separate linear guides or an additional motor.

However, due to its high cost, it’s not commonly seen in many machines today. Nevertheless, it is incorporated into machines that are sold at higher prices. The ball-screw and ball-nut system continues to be efficiently used in machining centers for precise positioning.

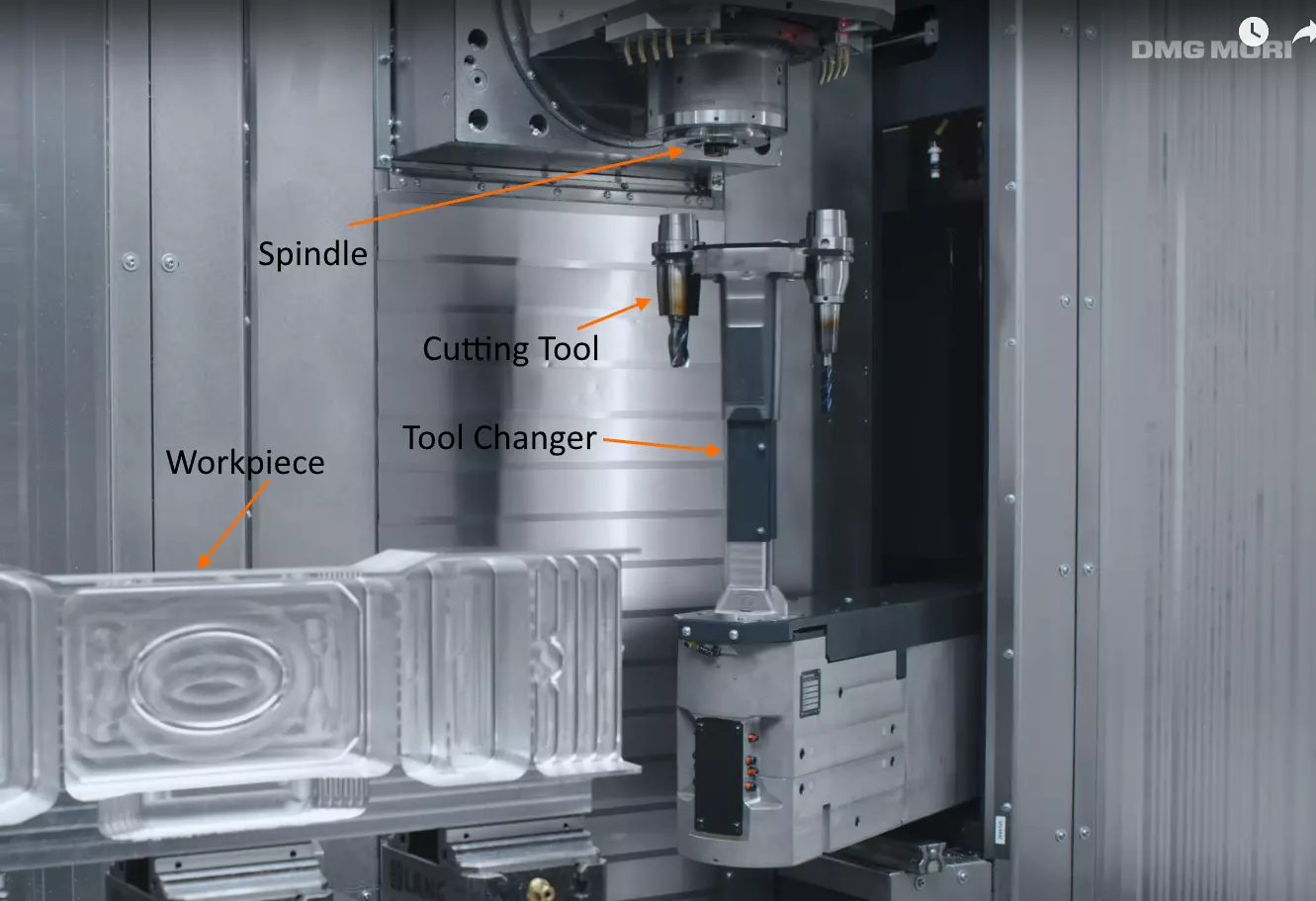

3-Automatic Tool Changer (ATC) System:

Automatic tool changers are one of the most critical components of machining centers. This feature sets machining centers apart from other CNC machines or conventional models. The need for such a feature arises from the fact that machining centers are known to operate for extended periods without human intervention. Through automatic tool changers(ATC), machining centers can automatically mount and dismount tools onto the spindle.

For example; the “T1 M6” G-code is commanding the CNC machine to mount tool NO-1. Additionally, with tool wear monitoring systems, the machine can provide necessary warnings, and based on these warnings, the machine can continue operating with minimal human intervention. These automatic tool changer systems can be constructed in varying capacities. For instance, machining centers generally have pockets for holding around 30 to 40 tools. Horizontal machining centers and universal machining centers, on the other hand, can have tool pockets ranging from 60 to 150.

Below you can see often-used Automatic Tool Chancer – ATC types:

- Carousel/Disk Type ATC: Revolving carousel storage; tools arranged around its circumference.

- Chain/Drum Type ATC: Loop-like chain system; that rotates in both directions for the shortest tool path.

- Matrix Type ATC: Grid storage system; tools placed in rows and columns.

- Linear Type ATC: Tools aligned in a straight line; orientation can be horizontal or vertical.

- Arm Type/Double Arm ATC: Swing arm mechanism; simultaneous tool drop-off and pick-up.

- Random Access/Memory ATC: No fixed sequence; directly selects any tool for flexibility.

- Bucket Type ATC: Carousel variation; bucket storage structure.

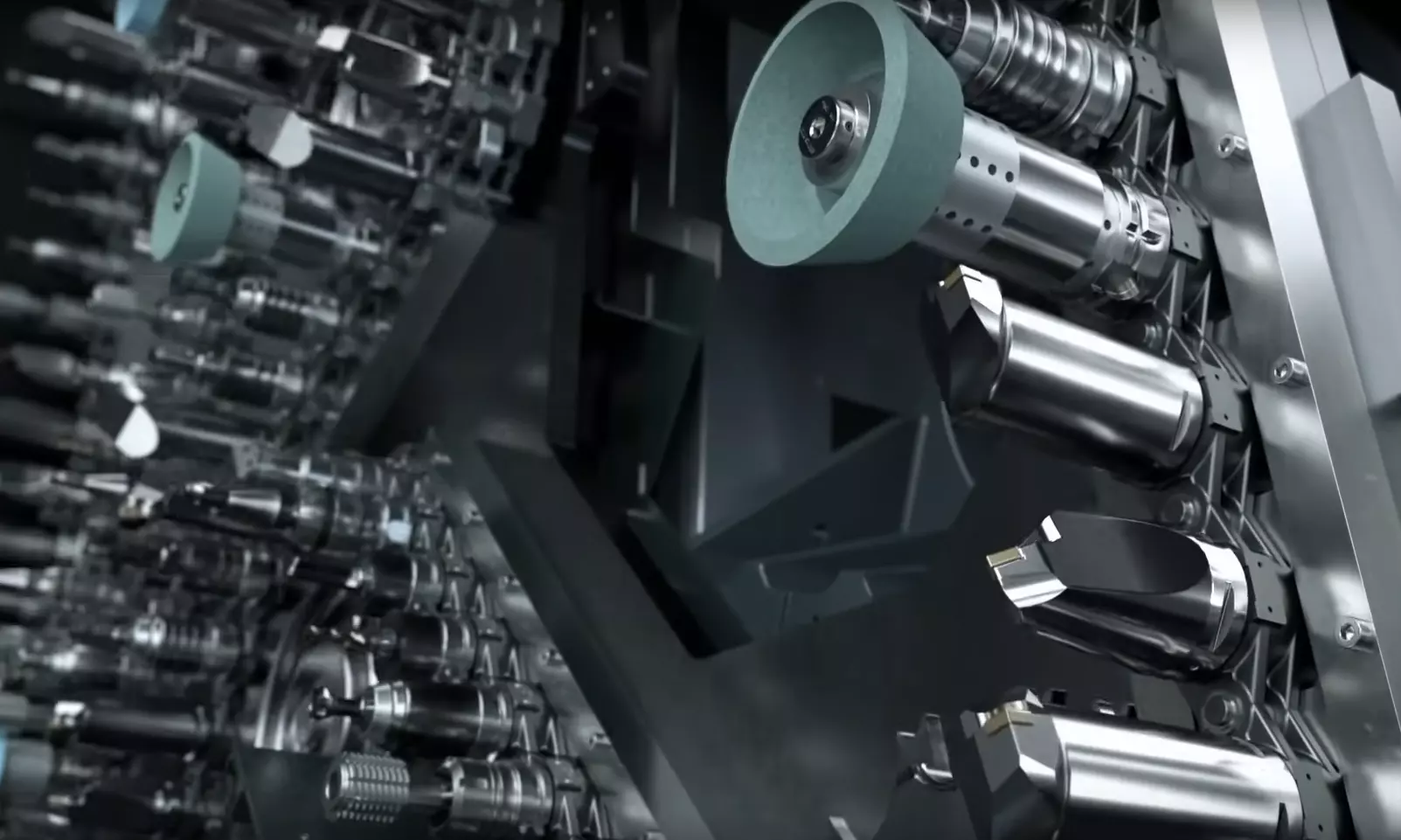

4-Tool Magazine and its Functionality:

In recent times, machining centers, especially horizontal and universal ones, have incorporated backup tool magazines and tool storage. To explain further, thanks to pallet changing systems, machining centers are equipped with the capability to operate automatically for days without human input, especially when dealing with large parts that require lengthy processing times.

However, this balance can be disrupted by the need to change tools due to wear. This involves stopping the machine for the replacement of worn or broken tools. To overcome this challenge, modern large machining centers come with dual tool changers. This means two tool changers are present in a single machine simultaneously.

For instance, let’s say a worn drill bit is in pocket 12. Normally, replacing this tool would require stopping production. However, with the modern backup tool magazine in place, machining centers can automatically replace the worn tool from the backup magazine. This enables the machine to run unmanned for extended periods.

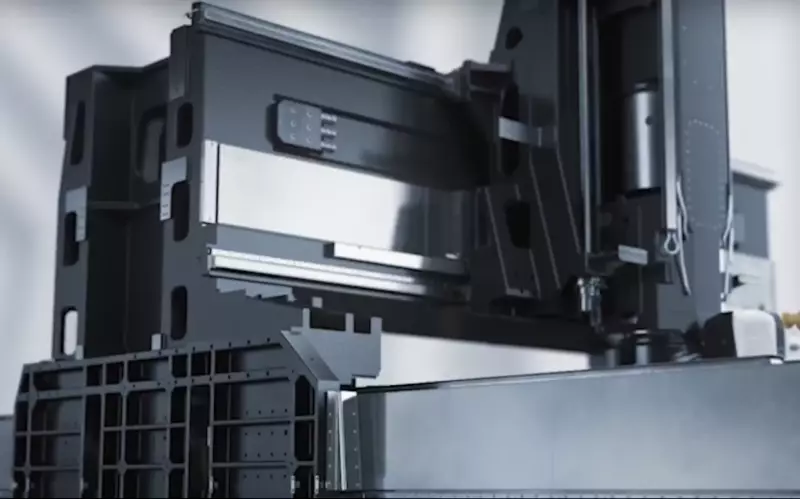

5-Automatic Pallet Changer (APC) System:

Automatic pallet changing systems enable machining centers to operate for longer periods without the need for human intervention. This enhances efficiency to the maximum level. After an operator loads a part onto one pallet, the machining center can immediately start processing that part. Meanwhile, the operator can set up the next batch of parts on another pallet. This eliminates part loading times, which is one of the significant advantages of machining centers.

Thanks to pallet changing systems, a machining center can line up multiple pallets, each containing different jobs. The machining center can call the necessary programs in sequence and carry out the processing. Machining centers can work continuously without stopping. This minimizes the transition time between parts and increases the machine’s overall operating time.

6-Automatic Head Changing System:

HMC, VMC, and UMC can carry some portable heads which include their built-in spindle. Those machining heads are generally produced to add 5-4-axis capabilities to machining centers. To make head handling easy machining centers have a system called Automatic Head Changer. This is very similar to ATC but it handles the mounting and unmounting process of the machining heads. Those heads are added as an upgrade to the spindle in order to change its angle to 90 DEG, or simultaneous angle head.

7-Chip and Coolant Handling System:

Machining centers are equipped with a crucial feature which is a chip and coolant management system. High-velocity coolant removes metal chips from the workpiece during the cutting process. The chips, which are carried away without adhering to the workpiece, are expelled from the machining center. However, these expelled chips often retain some of the coolant they came into contact with. Cutting fluid, mixed with the chips, creates a residue. At this point, machining centers automatically perform tasks like chip washing, drying, and removal, as well as placing chip carts to transport them away from the machine.

Another feature is the inclusion of through-spindle coolant systems that come with the machining center. Through-spindle coolant is particularly crucial for deep-hole drilling, especially in horizontal machining centers. However, nowadays, through-spindle coolant has become a standard feature not only in horizontal machining centers but also in vertical machining centers and universal machining centers. The high-velocity coolant spraying ensures that machining operations are effectively managed. This is important because chips that remain on the workpiece can disrupt operations, potentially damaging the finished part. If chips aren’t removed from the workpiece, they can break the tool and harm the part, as they cannot be expelled from the machine. So, chip clearance is a very essential aspect of the machining centers.

Safety Measures; Overload, Thermal Detection, Wear Monitoring, Door Automation:

- Overload: Tool overload, thermal deformation, and tool wear are among the most significant challenges in CNC machining. Tool overload often occurs when the spindle is subjected to excessive loads. Heavy cuts can strain the machine, causing servo motors to consume more energy. However, at times, these loads might exceed expected levels due to miscalculations. This is why machining centers are equipped with overload protection systems to safeguard against power fluctuations. Nowadays, thanks to artificial intelligence, machining centers can effectively detect tool overload and adjust the machine’s speed accordingly. This allows for better management of the machining process.

- Thermal Detection: CNC machines generate heat as a result of the cutting process. The rotational energy from servo motors, used for the cutting, is transformed into heat. Cooling systems, especially those that include cooling pipes passing through the machine’s structure and linear guides, are designed to prevent the machine from expanding thermally. Consequently, thermal sensors monitor these shape changes and temperature variations, enabling CNC machining centers to provide alerts and make adjustments as needed from their control panels.

- Tool Wear Monitoring: Tool wear monitoring is directly related to both tool overload and thermal expansion. In CNC machining centers, cutting tools consume more electricity as they wear out. Due to this, many machining center manufacturers measure tool wear, considering factors like resetting issues and machine spindle loads, to provide alerts and ensure that the operator takes the necessary precautions accordingly. This is essential because tool wear can be influenced by excessive loads and thermal expansion, ultimately affecting the machining process.

- Door Automation: Machining centers are often equipped with integrated automatic door opening and closing systems which are operated by linear actuators, particularly in the case of horizontal machining centers and universal machining centers. These types of machining centers are commonly used for processing large parts. Due to the potentially substantial sizes of the machines, opening and closing the doors manually can be a cumbersome task. To alleviate this challenge, advanced CNC machining centers incorporate automatic door mechanisms. This design eliminates the need for operators to manually handle the large doors. Reducing the risk of errors that could arise from forgetting to close or open the doors properly.

Practical Applications of Machining Centers

Machining centers are preferred by industries such as mold and Die manufacturing, automotive engine production, construction, and tool construction due to their capabilities in handling complex part manufacturing. These machines come in both smaller versions and especially large versions, suitable for processing medical components or even massive parts like train components.

Another significant application is in processing complex aviation and aircraft parts. For instance, machining centers are utilized with high precision to process wing frames and jet engine impellers.

Furthermore, machining centers find use in large-scale manufacturing processes. For example, gears can be processed with high precision on nine-axis mill-turn CNC machines, or even larger marine diesel engines can be efficiently handled using multiple nine-axis mill-turn CNC machines. And those processes repetitively can continue thousands of times without any problem. Repeatability is the key.

Investing in a Machining Center: Cost Implications

Factors Influencing the Cost of Machining Centers

Machining centers are generally more expensive than CNC routers and CNC lathes. There are several factors contributing to their higher cost. For example, larger-scale machines inherently require more materials, making them more expensive due to their size. Factors like robustness and speed also influence the price of these machines. For instance, if you’re a mold manufacturer, you might require high-speed capabilities, while an automotive parts manufacturer might need a device with medium-speed capabilities and precision.

Another factor is the brand reputation. Even if lesser-known brands produce equally capable machining centers, they might offer their machines at a lower cost than well-known brands, which often price their devices higher due to their established reputation.

Price Ranges for Different Types of Machining Centers

Speaking of price ranges, as previously mentioned, various factors can influence this, but generally, the cost can range from $100,000 to $3 million. To get a clearer picture, you need to determine the nature of your work, its intensity, and associated costs, allowing you to request quotes from machining center manufacturers accordingly. Some machining centers are huge and they need custom construction to set it up, I think the working area of the CNC machine in your workshop should be the first step. Japanese brands like OKUMA and MORI SEIKI specialize in decreasing the footprint of the machining centers they produce, so those machines can work even a smaller workshops.

I put here the current pricing from the well-known Haas brand:

Horizontal Machining Center price: Haas, EC-400, Starting at US$209,995

Vertical Machining Center price: Haas, VF-3, Starting at US$75,195

Universal Machining Center price: Haas, EC-1600ZT-5AX, Starting at US$438,995

FQA for HMC, VMC, UMC Machines

What is meant by machining center?

A Machining Center is a CNC machine capable of performing many standard and advanced machining operations like hole drilling, milling, boring, and tapping. It’s an all-in-one solution with tool and pallet changing functions.What is the difference between CNC and machining center?

While both are computer-controlled, machining centers are distinct from other CNC machines because they combine multiple functions and can complete complex operations without reflecting this complexity to the CNC operator.What is the function of machining center?

Machining centers perform various operations such as drilling, milling, boring, and tapping. They use computerized control systems, servo motors, and PLCs to manage tasks like changing tools, swapping pallets, and controlling probing cycles.What are the two basic types of machining centers?

The two basic types are Horizontal Machining Centers (HMC) and Vertical Machining Centers (VMC). There’s also a Universal Machining Center (UMC) that combines features of both.Is a machining center a mill?

A machining center can perform milling operations, but it encompasses more functionalities than a standard mill, such as tool and pallet changing capabilities.What is the characteristic of machining Centre?

Machining centers are known for their robustness, rigidity, efficiency, and the ability to perform complex operations. They often come with advanced features like Automatic Tool Changers, Automatic Pallet Changers, and chip and coolant management systems.What is VMC in CNC?

VMC stands for Vertical Machining Center. It’s a type of machining center where the spindle is positioned vertically. VMCs are compact, versatile, and can perform operations like engraving, hole drilling, and 3D surface machining.What is difference between CNC VMC and HMC?

The primary difference lies in the orientation of the spindle. In VMC, the spindle is vertically oriented, while in HMC (Horizontal Machining Center), it’s horizontally oriented. This affects the type of operations each is best suited for and their overall design.What is HMC in CNC?

HMC stands for Horizontal Machining Center. It’s characterized by its horizontal spindle orientation, ability to change palettes automatically, and its large cutting tool storage capacity.What are the applications of HMC machine?

HMCs are used by automotive part manufacturers, the aerospace industry, and the steel construction industry. They’re suitable for deep-hole boring operations and are inspired by conventional Horizontal Boring Machines.What is HMC working principle?

HMCs work by positioning the spindle in a horizontal orientation. They can automatically change palettes, machine all four sides of a pallet thanks to work-holding towers called Tomb-Stones, and have a large tool storage capacity. The horizontal orientation allows for efficient chip removal and deep-hole boring operations.Conclusion

Machining centers represent one of the prime areas where advancements in CNC technology are most commonly seen. These machining centers bring together various conveniences. Some of them are such as easing operations, simplifying programming, and facilitating processes. As you can imagine, ongoing developments and improvements are inevitable, and newer machining centers will undoubtedly include further advancements in CNC technology. CNC technology will evolve to achieve even greater heights in efficiency and performance.