- Importance of Understanding CNC Machine Types

- Some Basic Definitions

- The Main Components of a CNC Machine

- Understanding Different Types of CNC Machines

- Exotic Types of CNC Machines

- How Are CNC Machines Classified?

- Advantages and Limitations of CNC Machine Types

- Applications of CNC Machining

- How to Select the Best CNC Machine Type

- Conclusion

If you’ve ever found yourself puzzled by the multitude of different types of CNC machines, I’m here to guide you. In the early days of my career, I found just a couple of common types of CNC machines. At that time I initially thought CNC machines were limited to basic types like lathes and mills.

However, I soon discovered there was a CNC machine for almost every conventional machine. In this article, you will find a comprehensive list of CNC Machines with detailed explanations.

Also in this article, you can find a detailed explanation and list of CNC machines and their sub-types.

Importance of Understanding CNC Machine Types

Understanding CNC machines is more than just knowing their names. Their limits and purpose of manufacturing is the key point to understanding them.

For example, a CNC mill might excel at crafting intricate three-dimensional parts, but it could falter when dealing with cylindrical or rotational components. That’s where a CNC lathe comes into our workshop.

Likewise, factors like the machine’s weight, cost, and rigidity can greatly influence its appropriateness for a specific task.

A machine with high rigidity might be ideal for machining hard metals, but it could be excessive and costly for softer materials. By taking care of these points, you can make informed decisions.

Some Basic Definitions

Here is a list of the common terms that you will see on any CNC machine spec;

| Term | Description |

|---|---|

| Axis | Refers to the number of directions in which a CNC machine can move. A 3-axis machine can move in the X, Y, and Z directions. |

| Spindle | The part of the machine that holds and rotates the cutting tool. |

| Feed Rate | The speed at which the cutting tool moves through the material. |

| Rapid Traverse | The speed at which the machine moves when it’s not cutting. |

| Tool Path | The route taken by the cutting tool to machine the part. |

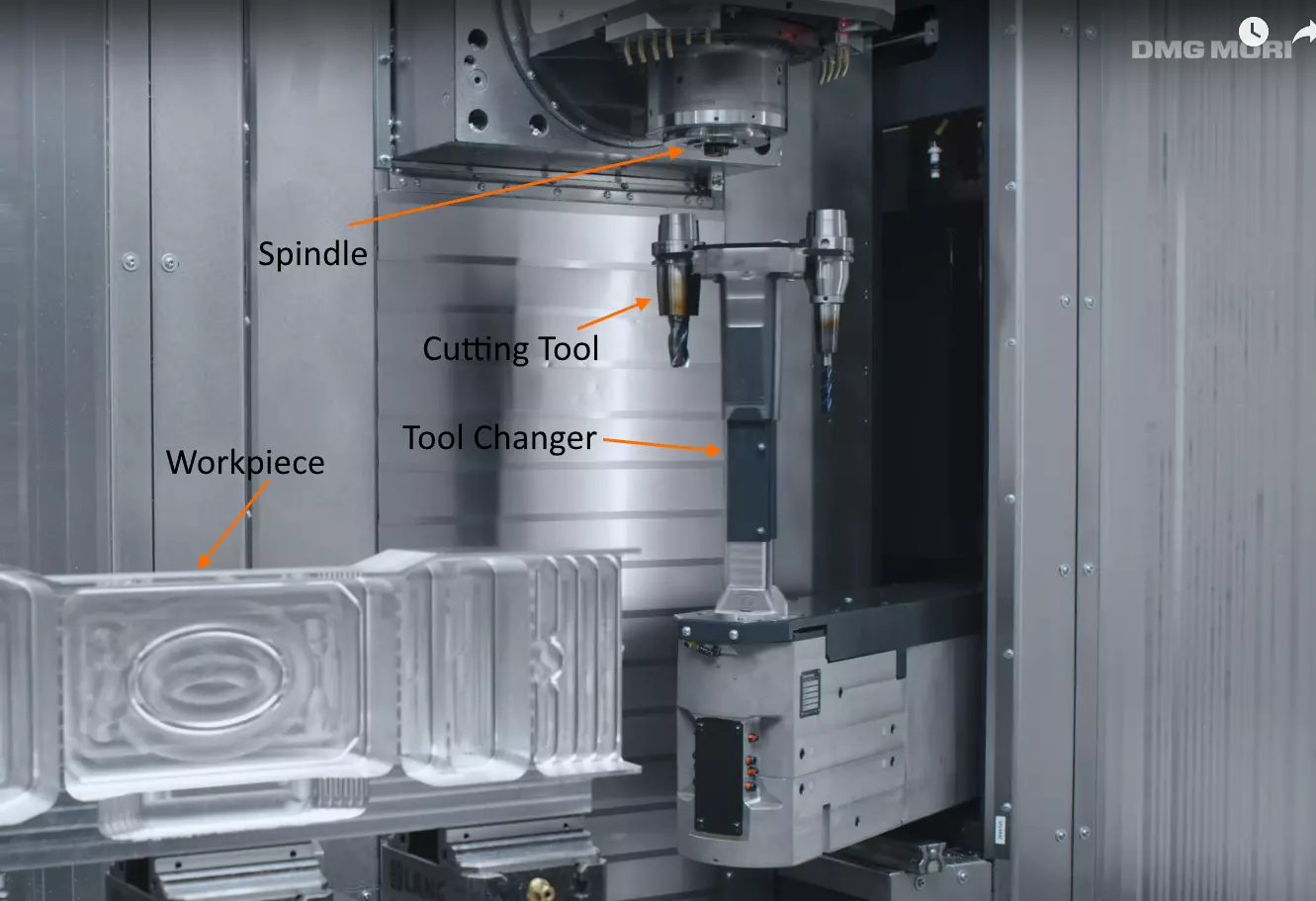

The Main Components of a CNC Machine

Some machines have different components than standard machines, but also there are some essential parts of a CNC machine.

- Controller: Consider this the machine’s brain. It deciphers the CNC program and dispatches instructions to the other components.

2. Spindle: As we touched on earlier, this is the component that secures and rotates the cutting tool.

3. Table: This is the designated spot where the workpiece is positioned and secured. Depending on the machine’s number of axes, the table can move in multiple directions.

4. Tool Changer: This component enables the machine to alternate between different tools during the machining process.

5. Coolant System: This system is responsible for cooling and lubricating the cutting tool and workpiece, which extends the tool’s lifespan and enhances the cut’s quality.

Understanding Different Types of CNC Machines

Let’s dive into the diverse world of CNC machines. Each type has its unique capabilities, making it suitable for specific applications. Here’s an overview of some of the most common types:

3D Printer

Unlike traditional CNC machines that remove material from a workpiece, 3D printers add material layer by layer to create a part.

This process is known as additive manufacturing. It basically adds melted material layer by layer. This allows for the production of complex geometries that would be difficult or impossible to achieve with subtractive(material removal) methods.

Router CNC Machine

Routers are typically used for cutting and shaping various materials like wood, plastics, and composites. They’re known for their versatility and are commonly used in woodworking, signage, and prototyping applications.

Drilling CNC Machine

As the name suggests, drilling machines are designed to create holes in workpieces. They can accommodate a variety of drill bit sizes and can create holes at precise locations and depths.

Lathe CNC Machine

Lathes are used for machining cylindrical or rotational parts. The workpiece rotates while the cutting tool shapes it, making lathes ideal for producing symmetrical parts with high precision.

5-Axis CNC Milling Machine

These machines can move in five different directions, allowing for the machining of complex parts in a single setup. This reduces the need for multiple setups and can significantly improve efficiency and accuracy.

Milling CNC Machine

Milling machines use rotary cutters to remove material from a workpiece. They can perform a wide range of operations like; cutting, drilling, and shaping, and can create intricate three-dimensional parts by 3D interpolation.

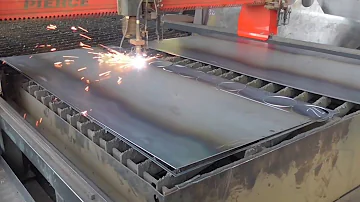

Plasma Cutting CNC Machine

Designed for cutting electrically conductive materials like steel, plasma cutters use a high-velocity jet of ionized gas (plasma) to perform cutting tasks. They excel at intricate shape cutting and profile creation.

Laser Cutting CNC Machine

Laser cutting machines can use laser beams to cut, and engrave the parts. They’re commonly used in sheet-metal cutting process.

Electric Discharge CNC Machine

Also known as EDM machines, these use electrical discharges to shape and erode conductive materials. Sharp corners of mold parts and complex shape production are very efficient with these machines.

Grinding CNC Machine

Grinding machines use an abrasive wheel to remove material from a workpiece. These days grinding machines can be used for machining parts from scratch before any premachining. Also widely used for precision grinding of mechanical parts as usual.

CNC Machine with Automatic Tool Changers

CNC machines with automatic tool changers are game changers also. Because it can sort and change tools automatically very fast machining times can be achievable with these machines. Today most modern CNC machines comes with automatic tool changer.

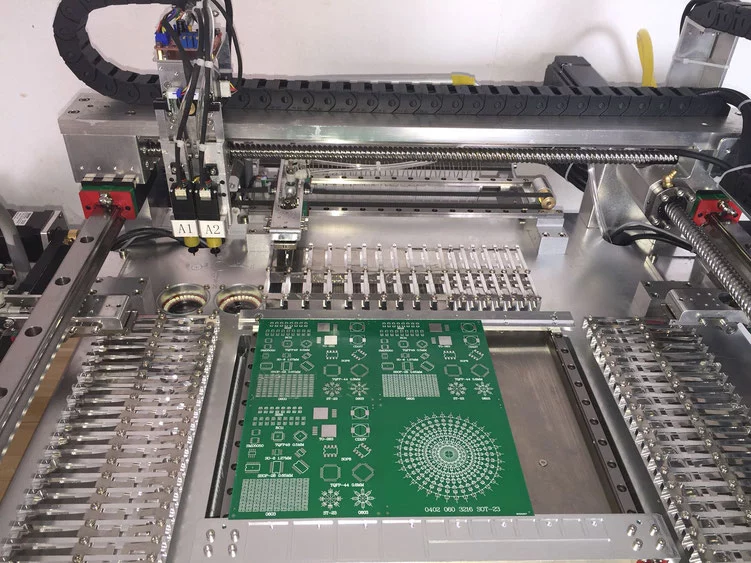

Pick and Place Machine

Pick and place machines are not involved with material removal but with placing the chips and other electronic components on a circuit board.

Remember, the best machine for you depends on the materials you’re working with, the complexity of the parts you’re producing, and your production volume.

Exotic Types of CNC Machines

Till now you just tasted common types of CNC Machines, however, there are also some more exotic types that are worth mentioning. These include:

- Water Jet CNC Machines: These machines use a high-pressure jet of water, sometimes mixed with an abrasive substance, to cut through materials. They’re great for cutting heat-sensitive materials. Because they don’t generate heat during the cutting process.

- Ultrasonic Machining (USM): This type of CNC machine uses ultrasonic vibrations to remove material. It’s useful for machining hard and brittle materials like ceramics and glass.

- Photochemical Machining (PCM): Also known as photo etching, this process uses light to etch material. It’s often used for producing intricate designs on metal surfaces.

How Are CNC Machines Classified?

CNC machines can be classified in several ways, including:

- By the number of axes: This refers to the number of directions in which the machine(table) can move. Common types include 3-axis, 4-axis, and 5-axis machines.

- By the type of operation: This includes milling, turning, drilling, grinding, etc.

- The control system: This refers to the type of control system used by the machine, such as computer numerical control (CNC) or manual control.

- The type of drive mechanism: This includes mechanical, hydraulic, and electric drives.

Advantages and Limitations of CNC Machine Types

Advantages

- Precision: CNC machines can produce parts with high precision and consistency.

- Versatility: They can perform a wide range of operations and can work with various materials.

- Efficiency: CNC machines can operate continuously and can produce parts faster than manual machines.

- Reduced Labor: CNC machines require less manual labor, which can reduce costs and improve safety.

Limitations

- Cost: CNC machines can be expensive to purchase and maintain.

- Complexity: Operating a CNC machine requires specialized knowledge and training.

- Limited Materials: While CNC machines can work with a wide range of materials, there are some materials that they can’t handle, such as certain types of plastics or glass.

- Energy Consumption: CNC machines can consume a significant amount of energy, especially larger industrial models.

Advantages and limitations can be changed according to some jobs. Production volume and budget can affect them.

Remember, the best machine for you depends on your specific requirements and constraints.

Applications of CNC Machining

Dental Supplies

Dentistry needs high-precision machines. Because of this CNC machines are used to create a variety of dental supplies, including crowns, bridges, and orthodontic appliances

Armaments

The armaments industry is supported heavily by CNC machine-manufactured components. From the intricate parts of a firearm to the complex components of a missile system CNC machines serve the industry with high precision and production rate.

Medium-sized but very precise machines are required for the Armaments industry.

Construction

Today gigantic CNC machines are widely used for contraction component manufacturing. Metal construction structures need high-precision parts. So CNC machinery is a good solution for this area.

Transportation

Whether it’s the automotive, aerospace, or maritime industry, CNC machines are integral to the production of various components. Automotive designers use CNC routers to machine real-world-size prototypes of their cars.

Development and Research

Today universities and research lab uses CNC machinery to manufacture experimental tools. Manufacturing prototypes are a key point.

Niche Production

CNC machines are also used in niche production like musical instrument manufacturing, furniture manufacturing, etc.

As you can see our modern society`s industry relies on many types of CNC machines.

How to Select the Best CNC Machine Type

Choosing and procuring the right CNC machine for your needs can be a hard process. You should consider some factors to achieve your requirements.

Here’s a guide to help you make an informed decision:

Consider the Cost of the Machine

CNC machines can vary significantly in price, depending on their capabilities, size, and brand. You need to understand that purchasing CNC machines is not just enough.

Employing an operator-programmer, tooling, and transportation of the machine, and placing the machine on the shopfloor must be considered before purchase.

below table shows a rough estimation of the cost of common CNC machines:

| Machine Type | Cost Range |

|---|---|

| 3D Printer | $200 – $20,000 |

| Router CNC Machine | $600 – $25,000 |

| Milling CNC Machine | $5,000 – $150,000 |

| Lathe CNC Machine | $5,000 – $100,000 |

Consider the Cost of the Parts

Some parts can be manufactured in high amounts with a dedicated special CNC machine. For example; if you want to produce screws, pins then Swiss-style lathes can be a good choice to beat the quoting competition.

Also having a Mill-Turn CNC machine can save you from buying a second milling machine to finish some features on the second setup.

Especially multiple spindle mill turns dedicated to finishing all parts in one machine.

Another example is a milling machine, If you want a machine Injection mold or vacuum mold buying a 5-axis machine with a large table area is cost-saving.

Consider the Procurement Process

The procurement process and abilities can affect the final cost of delivery.

Ordering spare parts, the lead time for machine delivery, and the level of customer support provided by the manufacturer are some of the important factors to consider.

I remember one of our machines was not working for almost 1 year because we couldn`t find the spare part.

Consider the Support and Training

Finally, consider the level of support and training provided by the machine manufacturer.

Operating a CNC machine requires a high level of hands-on skills. Machine training must be provided when needed. Because these machines are extremely stubborn and hard to learn.

Professional training will just open your way to produce better parts and will prevent the crashing CNC machine

With this knowledge, you can make a decision and choose the correct CNC machine for you. Remember, the best machine for you depends on your specific requirements and constraints.

It’s not always about choosing the most expensive or advanced machine, but rather the one that offers the best value for your specific needs.

Conclusion

For getting CNC machines, understanding the unique capabilities of each type is key.