Introduction

I came across a video on the Titans of CNC Machining youtube channel. This video was actually a video that all machinists were eagerly waiting for. The video touched on many facts about A. I CNC machining technologies. Therefore, I decided that I should write a good post about it. Today CNC technologies help us to machine mechanical parts faster, and cheaper. It is the locomotive of our modern life. All products need this technology. These days we have new breakthroughs in this area especially A.I. powered.

[email_subscription]

Below you can see watch the original video;

What is A.I. and How Does it Relate to AI CNC Machining and CNC Programming with AI

Maybe you’ve heard of Google Bard, ChatGPT, Open A.I. et cetera, these firms train their language models with machine learning methods. Since computer programs are in the trained position, these systems can learn information hundreds of times faster and deeper than a human.

The reason for all our fears actually starts here. Computers outperform people in every field they enter. These trained systems naturally have more knowledge than average people in AI CNC programming, Mechanical design, Mechanical science, and machining.

The man in the video emphasizes that he could not write a proper program with the artificial intelligence application CHATGPT by chance. He talks about the system doing a lot of things wrong, for example, he talks about cutting without turning the spindle with the M3 command.

I tried it too and I could achieve to get a proper G-code program perfectly. I found out the power of proper prompts and commands. However, still there is a huge chance to get wrong if you have a tiny prompt error.

[email_subscription]

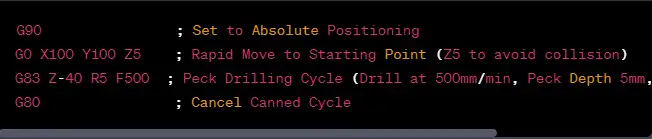

We don’t need many handwritten g-code programs these days, but they can be useful for small jobs.For example, you can ask ChatGPT for CNC machining with ChatGPT like this; “hey ChatGPT, can you drill a hole in steel with G-Codes in X100, and Y100 with 40mm depth, you decide the proper cycle and put suitable feed rates. Use 10mm, HSS Drill.”

I got this answer;

I totally got the Titans of the CNC guy`s point. The F500 feed rate is too much for steel and also there is a lot of G-code missing here.

What is the current situation in the CNC machining area with A.I.?

As the friend in the video mentioned, CNC technologies were introduced to artificial intelligence much earlier. World giants such as Mazatrol, Okuma, Fanuc, and Siemens had already started and adapted their artificial intelligence developments in both programming and machine management.

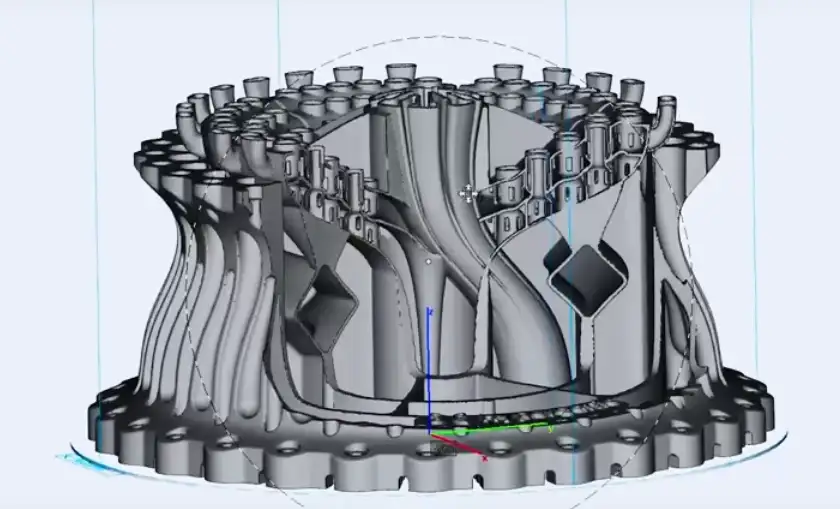

In addition, there were great breakthroughs in the field of CAD/CAM years ago. For example, 15 years ago, toolpath generation could be made from solid models automatically without selecting face and edge with TOPSolid CAD/CAM software.

At that time, we called this feature other than automatic processing, but it was actually artificial intelligence software running in it. It could even automatically determine the position of the cooler holes in mold designs and update the Parasolid model.

Compared to 15 years ago, they were very great technologies and were accepted by CNC machinists and mechanical designers. Today, at a time when artificial intelligence is spreading so fast, it is certain that we will see more advanced systems compared to 15 years ago.

Will AI CNC Machining, and Programming Replace CNC Machinists?

As conveyed in the video, the CNC machine is a human-oriented technology. When CNC machines first came to the market, all manual machinists had the same fear.

However, most of them realized that CNC machines were human-oriented and saw that these machines would increase production and precision by reducing the workload of humans and developed themselves to learn this technology.

Of course, those who did not accept this change at that time and continued manually disappeared from the market and lost their jobs.

In the same way, today, if anyone can keep up with this artificial intelligence revolution and improve themselves, they can find higher-paying jobs and have a better life.

After all, we will need qualified machinists to use artificial intelligence software, just as we need CAD/CAM operators.

What will be the Position of CNC Workshops in the AI CNC Machining Era?

Businesses, CNC workshops, and factories are in a more competitive and difficult position compared to workers. Because artificial intelligence software is making a breakthrough, and all of them enable these companies to produce parts quickly, precisely, and cheaply.

Naturally, these companies have to pay a lot of money to buy these technologies and teach them to their employees. This will bring along a great renewal that will be very costly. Companies that cannot afford this will have to leave the competition, and will and with leaving their place to larger companies.

Which Areas of CNC Programming with AI Will We See Improvements In?

Artificial intelligence has already begun to be used in some areas. For example, companies such as Okuma and Mazak have developed software that monitors the thermal and vibration status of the machine and adjusts the machine in real time without the operator’s involvement.

Tool manufacturers such as Sandvik have also developed technologies that make the cutting process more controllable, with Silent Tools eliminating the vibrations of long cutting tools and adjusting the machine with real-time feedback. Also, they created a packaging system that controlled A.I. technology.

Moreover, these studies have led to developments not only directly in CNC machines and programs but also in the workshop office area. For example, DMG Mori made a 3d part pricing engine. This Quoating engine can automatically recognize 3d models and do cost estimation.

[email_subscription]

Summary

In summary, the implementation of AI in CNC machinings, such as AI CNC machining and CNC programming with AI, will ensure the security of CNC machinist employment as long as they are receptive to new technologies and focus on self-improvement. Machine operators are winners in this era. Programming and design need ongoing creativity and human interaction.

Manufacturing has improved because of CNC and AI. CNC machines can learn, adjust, and optimize themselves thanks to A.I., which boosts output, precision, and efficiency. Industry experts are concerned about how this development may affect the workforce and the sector.

The uptake of AI could be delayed and steeper. The potential and difficulties of AI in CNC machining are discussed in this article along with the prospects for the sector in the AI age.