- The Evolution of AI in CNC Programming and Machining

- Timeline of AI Advancements in CNC Machining and Programming

- ChatGPT: CNC Programming Through AI-Language Models

- Pioneering Companies in AI-Powered CNC Solutions

- The Benefits of AI-Powered CNC Machines

- CAM Software Innovations with AI

- The Relevance of G-Code Programming in the Age of AI

- Conclusion

- FQA for AI Machining

- What is the role of AI in CNC programming and machining?

- Which companies are leading the way in AI-powered CNC solutions?

- How does AI enhance CAM software?

- Is G-Code programming still relevant in the age of AI?

- What are the advantages of AI-driven CNC programming over human-driven programming?

- How does AI help in reducing errors and inconsistencies in CNC programming?

The Evolution of AI in CNC Programming and Machining

In this post, we will explore the impact of artificial intelligence on CNC programming and CNC machining, with a focus on innovative AI-driven CNC solutions from leading companies like DMG Mori, Mazak, and Okuma.

Discover how AI is transforming CNC processes, including G-Code programming, and improving efficiency, precision, and productivity.

From its early days in computing, the integration of artificial intelligence (AI) into computer numerical control (CNC) programming has been a story worth telling. The 1970s saw the birth of AI in this field, as basic rule-based systems were deployed to generate CNC code.

Technology continued to rapidly advance in the 21st century. The development of AI algorithms reached new heights, leading to their widespread use across various industries.

AI’s most memorable milestone was when Deep Blue, an AI program, defeated a human chess player, showcasing the immense potential of AI and drawing attention to its boundless possibilities.

The below table shows how AI-based technologies growing rapidly;

That time World of manufacturing has experienced significant growth and transformation over the years.Especially in the realm of computer numerical control (CNC) machining area.

As a result, manufacturers are now seeking to harness the power of artificial intelligence (AI) to optimize their CNC processes(like programming, and machining) to drive efficiency and improve overall product quality.

[email_subscription]

In this article, we will explore the role of AI in CNC programming, discuss some of the leading companies in this field, and delve into the potential impact of AI-driven CNC solutions on the manufacturing industry.

Timeline of AI Advancements in CNC Machining and Programming

I made a timeline to clear up AI advancements in the CNC machining and programming area.

1970s: Basic rule-based systems are used to generate CNC code, marking the beginning of AI’s involvement in CNC programming.

1980s-1990s: Significant advancements are made in computer technology, leading to the development of increasingly sophisticated AI algorithms.

1997: Deep Blue, an AI algorithm, defeats a human chess player, attracting global attention to the potential of AI.

2000s: AI continues to be integrated into various industries, including CNC programming and machining.

2010s: The rapid advancement of computer technology led to the development of more advanced AI algorithms and their integration into CNC machining and programming.

2020s: AI continues to be integrated into CNC machining and programming, leading to improved efficiency, precision, and productivity in the manufacturing industry. The use of AI in CNC machining and programming has become increasingly widespread.

ChatGPT: CNC Programming Through AI-Language Models

ChatGPT, an AI language model developed by OpenAI, is poised to revolutionize CNC programming by generating optimized and efficient programs.

By leveraging its advanced natural language processing capabilities, ChatGPT can understand complex machining requirements and generate G and M codes tailored to the specific needs of a project.

This innovative AI solution can save significant time and effort in the programming process while reducing the margin of error associated with manual programming.

By utilizing ChatGPT in CNC programming, manufacturers can benefit from the following advantages:

- Rapid program generation: ChatGPT can quickly generate CNC programs, enabling manufacturers to accelerate their production timelines and meet tight deadlines.

- Improved program quality: The AI-driven language model can analyze historical data and generate optimized programs that improve machining efficiency and reduce tool wear.

- Enhanced adaptability: ChatGPT’s advanced algorithms allow it to adapt to new and changing machining requirements, ensuring that generated programs remain up-to-date and relevant.

- Reduced reliance on skilled programmers: As ChatGPT can generate CNC programs with minimal human intervention, manufacturers can reduce their dependence on skilled CNC programmers and allocate resources more effectively.

[email_subscription]

Pioneering Companies in AI-Powered CNC Solutions

DMG Mori, Mazak, and Okuma are some of the leading companies in the field of AI-powered CNC machines industry. These companies are well known for staying ahead of the edge in terms of technology in the market.

It is worth mentioning these companies have developed AI-inspired solutions that have improved the manufacturing process, bringing efficiency and precision to CNC programming and machining.

1. DMG Mori

DMG Mori is a global leader in machine tool manufacturing. They are forehead integrate AI systems into their CNC machines.

The company’s AI-enhanced solutions are designed to improve machine performance, increase productivity, and reduce errors in the manufacturing process.

Their AI-driven technologies include intelligent monitoring systems that optimize the machining process.

More advanced AI algorithms automatically adjust cutting parameters to minimize tool wear and extend tool life.

2. Mazak

Mazak, another giant in the CNC industry, has been developing AI-powered technologies to transform manufacturing. They have introduced AI-assisted programming features that enable their machines to learn from historical data and generate optimized machining strategies.

Their AI-enhanced systems also include real-time process monitoring, which helps identify potential issues before they become critical, significantly reducing downtime and improving overall productivity.

Also, their Mazatrol SmoothAi system is capable of generating toolpaths directly from the Mazatrol controller with minimal human interaction for solid models.

3. Okuma

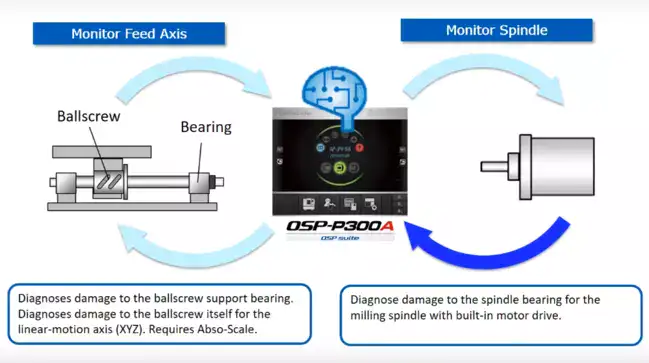

Okuma, a renowned name in the CNC machine tool industry, has also embraced AI-driven solutions to enhance their manufacturing capabilities.

Okuma AI systems collect data from highly sensitive sensors and optimize machine operations in real time. Their CNC machines are also capable of measuring vibration and adjusting cutting speeds in real time.

4. Fanuc

Fanuc, a leading manufacturer of CNC machines, integrated AI into its systems to revolutionize manufacturing.

Their AI-powered solutions are designed to improve machine performance and increase productivity by analyzing data from sensors and automatically adjusting cutting parameters in real time.

This allows their CNC machines to operate more efficiently and effectively, reducing downtime and errors in the manufacturing process.

5. Siemens

Siemens, a global technology company. Their AI-driven technologies include advanced algorithms that analyze data from sensors and optimize machine operations in real-time.

These systems reduce downtime and improve overall productivity. Also, Siemens`s AI systems use historical data to predict the best machining operations and strategy.

The Benefits of AI-Powered CNC Machines

To understand the transformative power of AI in CNC programming, let’s compare human-driven machining with AI-driven machining:

- Speed: AI-driven machining can generate programs more rapidly than human programmers, significantly reducing programming time.

- Precision: AI algorithms can optimize toolpaths and improve overall machining accuracy, resulting in higher-quality products.

- Adaptability: AI-driven solutions can easily adapt to changing machining requirements, ensuring that programs remain relevant and effective.

- Learning: AI systems can learn from historical data and continually improve their programming capabilities, whereas human programmers may be limited by their experience and knowledge.

- Error reduction: AI-powered CNC programming can minimize errors and inconsistencies, leading to improved product quality and reduced production waste.

CAM Software Innovations with AI

The integration of AI into computer-aided manufacturing (CAM) software has brought about a new era in CNC programming.

Such as Autodesk’s Fusion 360 and Mastercam, now utilize AI algorithms to streamline the programming process, optimize toolpaths, and predict potential machining issues.

These AI-driven CAM software solutions not only save time and reduce programming errors but also help manufacturers achieve higher levels of precision and efficiency in their machining processes.

The Relevance of G-Code Programming in the Age of AI

Despite the rapid advancement of AI in CNC programming, G and M codes remain relevant in the manufacturing industry. These codes, which are used to control CNC machine movements and operations, still play a vital role in many quick turnaround jobs and specialized applications.

While AI-driven solutions are increasingly automating the programming process, there will always be a need for skilled CNC programmers who understand the intricacies of G and M code programming to handle unique projects and specific requirements.

As the manufacturing landscape continues to evolve, the importance of G and M code programming remains relevant, but the potential impact of AI-driven solutions like ChatGPT, and Google Bard cannot be ignored.

By embracing AI-enhanced G-Code CNC programming, manufacturers can ensure that they remain at the forefront of innovation and maintain their competitive edge in the ever-changing world of manufacturing.

Conclusion

I really think the integration of artificial intelligence into CNC programming is revolutionizing the manufacturing industry by streamlining processes and improving efficiency. Those things will improve precision too.

Pioneering products like Google Bard and ChatGPT and companies like DMG Mori, Mazak, Okuma, and innovative CAM software solutions are leading the way in embracing AI-driven technologies that promise to transform CNC machining.

In Mechutopia we got a responsibility to provide some work about his area. You can this article which looks with a bird’s eye view at the modern CNC machinist’s current position in the AI era.