- 1. Introduction

- 2. Understanding Machining

- 3. Detailed Comparison CNC Machining vs. Manuel Machining

- 4. The Pros and Cons of CNC and Traditional Machining

- 5. Making the Right Choice: CNC or Traditional Machining?

- 6. Scenario-Based Example Shows How You Can Choice CNC or Manuel Machining

- 7. Conclusion

- What are the main differences between CNC machining and manual machining?

- How did CNC machining revolutionize the manufacturing industry?

- What are the advantages and disadvantages of using CNC machining?

- What are the advantages and disadvantages of using manual machining?

- How do I decide whether to use CNC or manual machining for my project?

- What factors should be considered when selecting a machining method?

1. Introduction

Are you a professional investor or a workshop owner? Or, are you just a CNC apprentice or hobbyist? I’m sure many of you have had a period in your life when you thought a lot about the differences between CNC machining and manual machining technologies.

Many people, including myself and you, have likely experienced this. In this post, I will explain and compare CNC machining and manual machining. I will also discuss the pros and cons of each method and answer common questions on the topic.

Whether it’s the precision crafting of a delicate watch component or the robust shaping of an aircraft part, machining techniques play a pivotal role. The art and science of transforming raw materials into finished products, machining is a cornerstone of our modern industrial landscape.

It’s a process that brings designs to life, turning theoretical concepts into tangible, functional objects. From the smallest screw to the largest engine block, machining is the magic that makes it all possible. Whether it’s traditional manual machining or the cutting-edge realm of Computer Numerical Control (CNC), these

2. Understanding Machining

Traditional machining, or manual machining, emerged during the industrial revolution with the improvement of machine tools like lathes and milling machines.

Computer Numerical Control (CNC) machining was a new era in the mid-20s. This technology, which automates machine tools using computers, revolutionized the field, offering high precision, consistency, and efficiency. The journey from manual to CNC machining reflects our relentless pursuit of precision and efficiency. As we continue to innovate, the future of machining promises to be as thrilling as its past.

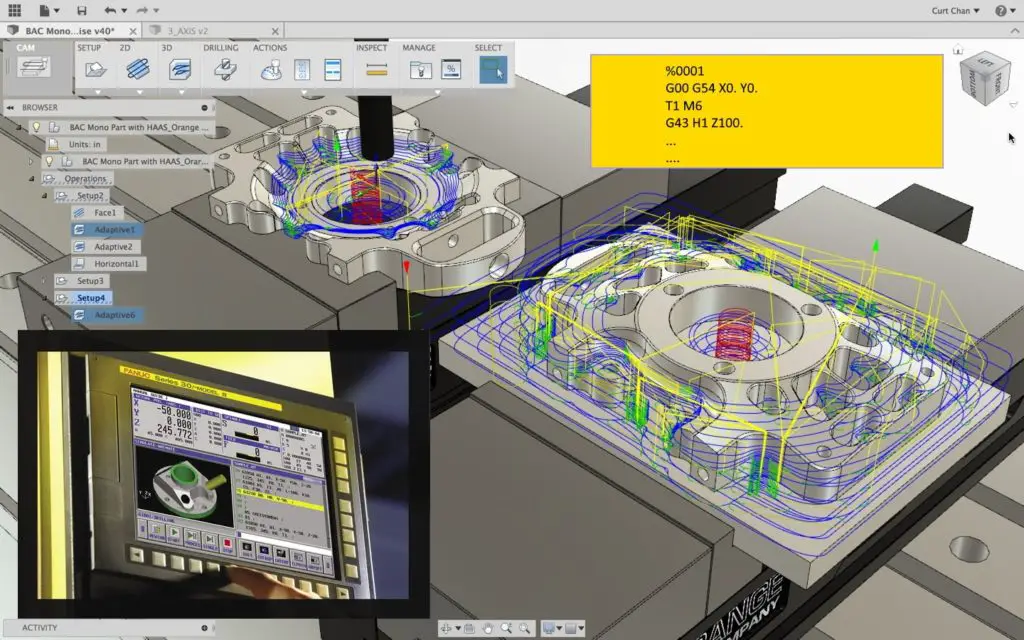

a. CNC Machining

CNC Machining, or Computer Numerical Control Machining, is a manufacturing process where a pre-programmed computer with G-Codes dictates the movement of factory tools and machinery. This process allows for precise control of a range of complex machinery, from grinders and lathes to mills and routers. With CNC machining, three-dimensional cutting tasks can be accomplished in a single set of prompts, offering unparalleled precision and repeatability.

The mechanics of CNC machines are a marvel of modern engineering. At the heart of each CNC machine is a controller—a computer that is fed a digital file containing specific instructions for the machining task. This computer then controls the movement of the machine’s tools, directing their speed, coordination, location, and feed rate. The machine’s tools are mounted on a movable table, allowing for movement and operation in multiple axes—up to five in some advanced machines.

The most common CNC machines are mills, which work by cutting materials, such as metal or plastic, from a block. Lathes, another type of CNC machine, cut workpieces as they are rotated with an RPM. Other types of CNC machines include plasma cutters, electric discharge machines(EDM), and multi-axis machines, each offering unique capabilities and advantages.

Most of the other CNC machines are delivered from Mills and Lathe. For example, a Horizontal machining center(HMC) is a milling machine but it is designed to work horizontally to handle large parts. On the other hand, a Swiss turn-style CNC lathe machine is a lathe but with longer material feed and complex tooling capabilities.

CNC machining has revolutionized the manufacturing industry, offering a level of precision and efficiency that traditional(manual) machining techniques simply can’t match.

| Benefits of CNC Machines | Explanation |

|---|---|

| Precision and Consistency | CNC machines can produce parts with a high degree of accuracy, and they can replicate this precision across multiple parts, ensuring consistency in high-volume production runs. |

| Complexity | CNC machines can produce complex shapes and designs that would be difficult or impossible to machine manually. |

| Speed | CNC machines can operate continuously, without the need for breaks, leading to faster production times. |

| Safety | Since the machining process is automated, there’s less risk of operator injury. CNC machines come with cabinetry that protects the operator from coolants and the effect of machine crashes. |

| Efficiency in High-Volume Production | CNC machines are particularly effective for high-volume production runs due to their speed, consistency, and automated nature. |

| Better Handling of Hard Materials | CNC machines often have the edge when it comes to harder materials or complex shapes, thanks to their precision and consistency. |

| Automated Tool Changing | CNC machines have an Automatic Tool Changer (ATC) that can store tools and call them when needed in a CNC program, saving time and effort in high-volume production. |

| Reduced Operator Error | Since the machine is controlled by pre-programmed software, there’s less chance of errors due to manual operation. |

| Better for Complex Projects | CNC machines are often used in industries like aerospace and automotive where high precision and complex machining is required. |

| Less Time-Consuming | CNC machines, due to their automated nature, can complete tasks more quickly than manual machines, especially for large production runs. |

b. Traditional(Manuel,Conventional) Machining

Traditional machining is often used for “Manual Machining” or “Conventional Machining”. It is a time-consuming manufacturing process that involves the manual operation of various tools and machinery to cut or form a piece of material. Turning, milling, drilling, and grinding most common manual machining techniques among others. Unlike CNC machining, traditional machining requires a high level of operator skill and direct control, as the machinist manually operates the tools and machinery.

In traditional machining, the lathe is one of the commonly used machine tools. It works by rotating a workpiece around a stationary cutting tool, allowing for the creation of symmetrical objects like cylinders and spheres. On the other hand Milling machines use rotary cutters to remove material from a workpiece.

When compared to CNC machining, traditional machining has unique properties. If you think controlling a machine’s every movement by your hand is Manual machines give that to you. Since the machinist is directly operating the tools and machinery, they can make adjustments on the fly, allowing for a high degree of flexibility. This makes traditional machining particularly well-suited for one-off projects or small production runs.

Conventional Manuel machines cannot provide the precision, consistency, and speed of CNC machining. Manual operations are inherently more prone to errors and inconsistencies and generally take longer than their automated counterparts. Nowadays finding skilled manual machine operators getting harder and harder.

3. Detailed Comparison CNC Machining vs. Manuel Machining

To understand the differences let’s delve into a comparative analysis of these two pivotal machining techniques.

a. Comparison of the Processes

CNC machining is a computer-driven process that offers high precision, accurate position repeatability, and speed. It’s particularly well-suited for complex parts and high-volume production runs. The pre-programmed software controls the movement of the tools, ensuring consistent and accurate results every time.

On the other hand, traditional machining involves manual operation of the tools and machinery. It offers flexibility and full control, making it ideal for one-off projects or small production runs. The downside is it requires a skilled operator and can be more time-consuming than CNC machining.

b. Comparison of the Skillsets Required

CNC machining requires knowledge of computer programming and CAD/CAM software. Also, nowadays the operator needs to create 3D Solid models and make 2d technical drawings for manufacturing needs.

Traditional machining requires a deep understanding of the tools specially used for manual machining. Also, a strong steady hand can make adjustments on the fly. For example, I learned from my hands-on experience that, climb milling must be avoided while you are using a manual mill. Because of the looseness of the machine table (screws, nuts, and guide bushes) tool can grap part with a sudden move and brake tool and part.

c. Comparison of the Materials That Can Be Used

Both CNC and Conventional Manuel machines can work with most engineering materials. Like metals, plastics, and wood. However, CNC machining often has the edge when it comes to harder materials or complex shapes, thanks to its precision and consistency.

d. Comparison of the Typical Projects Undertaken

CNC machining is typically used for high-volume production or complex parts that require a high degree of precision. It’s often used in elite industries like aerospace, and automotive.

Traditional machining, meanwhile, is often used for custom projects, prototypes, or small production runs. It’s commonly used in job shops, repair shops, and artisan workshops.

From my experience, I had found manual machining is very flexible and fast if you need to machine a small feature like a keyway, or a hole in a part. Just for a single part setting up a CNC machine can cost more instead of just machining it manually.

Don’t be shocked! Sometimes I also use CNC machines like manual machines in handwheel mode. Because you can use the machine very easily manually in this mode. Also, MDI mode on a CNC machine can be used for simple single-part machining.

e. Comparison of Feeds and Speeds

This is another important consideration. You must think always about different feeds and speeds for CNC Machines and Conventional Machines. CNC machines are generally designed to speed up all processes. For example, using through coolant is a good example of how CNC machining speeds up drilling by cooling the drill better. Through coolant, Rigid machine frame, and high spindle speed RPM energies you to use different Feeds and Speeds spectrum.

On the other hand; Manuel machines have limited Speeds and feeds, also Manual machines do not come with a safety cabinet, so working with high speeds and feeds must bu be avoided because operators must work very close to the device to use movement handles.

f. Comparison of Tooling

All machining operations happen with a cutting tool, handling the tool is one of the important things to compare when we think about machining.

CNC machining like I said before is repetitive and able to produce 10s,100s, and 1000s of parts easily. For that much manufacturing capacity, CNC machines conveniently handle the cutting tools. ATC ( Automatic Tool Changer ) is one of the important parts of a CNC machine. With this tool magazine, we can store tools and call them when we need them in a CNC program.

Also, the tool-changing process is handled by the ATC, so the operator even does not need to touch it after setting it. It has a special arm that grabs tools from the tool magazine and mounts to the spindle perfectly. When you machine thousands (1000) of parts it is unbelievable how much time and effort you will save with CNC machines.

In contrast, Conventional machines are not good at tool handling. Manuel Machining requires also manual tool changing. That is why high-volume manufacturing is not suitable for manual machining. Let’s say 1000 parts need to be machined, then it means the manual machine (Mill, Lathe, Bohrwerk, etc.) operator needs to change and set the tools thousands of times depending on how many tools are used. It can be multiplied easily.

For example; if a manual Mill operator uses 4 tools to machine a part, it means for 100 parts operator needs to change tools 4*100=400 times. You got the point. It is too much for an operator to change that much tool.

4. The Pros and Cons of CNC and Traditional Machining

Both CNC and traditional machining have their unique advantages and disadvantages. Let’s delve into a detailed analysis of each.

CNC Machining

Advantages:

- Precision and Consistency: CNC machines can produce parts with a high degree of accuracy, and they can replicate this precision across multiple parts, ensuring consistency in high-volume production runs.

- Complexity: CNC machines can produce complex shapes and designs that would be difficult to machine manually.

- Speed: CNC machines can operate continuously, without the need for breaks, leading to faster production times.

- Safety: Since the machining process is automated, there’s less risk of operator injury.CNC machines come with cabinetry that protects the operator from coolants and the effect of machine crashes.

Disadvantages:

- Cost: CNC machines and their maintenance can be expensive, making them less accessible for smaller operations.

- Training: Operating a CNC machine requires computer knowledge. Also, a wide range of CAD/CAM systems makes it harder to find specialized operators.

- Less Flexibility: CNC machines can produce the same part again and again, but when it comes to customized single parts it sucks.

- Setup: It requires a proper part setup, and tool magazine setup before starting machining.

Traditional Machining

Advantages:

- Flexibility: Traditional machining is highly flexible, allowing for adjustments on the fly. This makes it ideal for custom projects and prototypes.

- Lower Initial Cost: Manuel machines are generally cheaper than CNC machines, making them more accessible for smaller operations or hobbyists.

- Simplicity: Traditional machining doesn’t require knowledge of programming or complex software, making it more straightforward to learn and operate.

Disadvantages:

- Less Precision and Consistency: While a skilled machinist can achieve high precision, manual machining is generally less consistent than CNC machining, particularly for high-volume production runs.

- Slower Production: Manual machining is typically slower than CNC machining, particularly for complex parts or large production runs.

- Safety Risks: Since the operator is directly handling the machines, there’s a higher risk of injury compared to CNC machining.

5. Making the Right Choice: CNC or Traditional Machining?

It would help if you considered several factors to select the proper machining method for your needs. Think about those key considerations.

- Volume: If you’re looking at a high-volume production run, CNC machining is typically the better choice thanks to its speed and consistency. For smaller runs or one-off pieces, traditional machining may be more cost-effective.

- Complexity: For complex parts with surface designs, CNC machining’s precision, and ability to machine complex NURBS surfaces. Traditional machining, while flexible, but not suitable for machining complex parts. Think you are machining an injection mold for a car part, manually machining those complex surfaces is almost impossible with manual machines.

- Cost: CNC machines can be more expensive initially. CNC shines on high-volume and long-run jobs. Because repeatability is a key power in CNC machining. Traditional machines, have lower upfront costs but may be more time-consuming and less efficient for larger runs.

- Skillset: CNC machining requires knowledge of programming and CAD/CAM software, while traditional machining requires manual skills and direct machine operation. The available skillset can influence the choice between the two.

Industry-specific needs also play a role in the selection process. For example, in industries like automotive, Medical, and Aerospace high precision machining is a must-go way. On the other hand, job shops, repair shops, and hobby workshops may prefer the flexibility of traditional machining.

6. Scenario-Based Example Shows How You Can Choice CNC or Manuel Machining

All scenarios come with points and a final result shows the winner for the scenario. You can see all benefits of CNC machining and Manuel Machining. According to the scenario, you will also see the Disadvantages of CNC machining and Manuel Machining.

a. Possible Scenario For Choice Of CNC Machining Over Manuel Machining.

Scenario-1: 100 parts need to be machined with high precision.

| Criteria | CNC Machining | Points | Manual Machining | Points |

|---|---|---|---|---|

| Precision | High precision is a key strength of CNC machining. | 3 | Manual machining is generally less consistent. | 1 |

| Volume | CNC machining is well-suited for high-volume production runs. | 3 | Manual machining may be more time-consuming for producing 100 parts. | 1 |

| Speed | CNC machines can operate continuously without breaks. | 3 | Manual machining is typically slower for large production runs. | 1 |

| Consistency | CNC machines can replicate the same precision across all 100 parts. | 3 | Manual operations are more prone to errors and inconsistencies. | 1 |

| Tool Handling | CNC machines have an Automatic Tool Changer (ATC). | 3 | Manual machining requires manual tool changing. | 1 |

| Safety | CNC machines come with safety cabinets and the process is automated. | 3 | There’s a higher risk of injury with manual machining. | 1 |

| Cost Efficiency | CNC machines can be more cost-effective in the long run for high-volume jobs. | 3 | Manual machines may be less efficient for larger runs. | 1 |

| Total Points | 21 | 7 |

Scenario-2: 20 parts need to be machined with medium-level precision.

| Criteria | CNC Machining | Points | Manual Machining | Points |

|---|---|---|---|---|

| Precision | CNC machining can provide high precision, but medium precision is also achievable. | 2 | Manual machining can achieve medium precision with a skilled operator, but consistency may be a challenge with 20 parts. | 2 |

| Volume | CNC machining is efficient for high-volume production. For 20 parts, the setup time is likely worth it. | 3 | Manual machining is suitable for small production runs, but 20 parts may be pushing the limit. | 2 |

| Speed | CNC machines can operate continuously without breaks, making them faster for 20 parts. | 3 | Manual machining may be slower, especially for 20 parts. | 1 |

| Consistency | CNC machines can replicate the same precision across all 20 parts. | 3 | Manual operations may have slight inconsistencies, especially with 20 parts. | 1 |

| Tool Handling | CNC machines have an Automatic Tool Changer (ATC) that can handle multiple tools efficiently. | 3 | Manual machining requires manual tool changing, which can become time-consuming with 20 parts. | 1 |

| Safety | CNC machines come with safety cabinets and the process is automated. | 3 | There’s a risk of injury with manual machining, but for 20 parts, the risk may be manageable. | 2 |

| Cost Efficiency | The setup time and cost for CNC machines are likely worth it for 20 parts, especially if multiple tools are needed. | 3 | Manual machines may be less cost-effective for producing a larger number of parts. | 2 |

| Total Points | 20 | 11 |

a. Possible Scenario For Choice Of Manuel Machining Over CNC Machining.

Scenario-3: A single part needs to be machined without high precision.

| Criteria | CNC Machining | Points | Manual Machining | Points |

|---|---|---|---|---|

| Precision | High precision may not be necessary for this part. | 1 | Manual machining can be sufficient for a part that does not require high precision. | 3 |

| Volume | CNC machining is more efficient for high-volume production. | 1 | Manual machining is more suitable for one-off pieces. | 3 |

| Speed | The setup time for a single part may outweigh the speed advantage. | 1 | For a single part, the difference in production time may not be significant. | 3 |

| Consistency | Consistency is not relevant for a single part. | 1 | Consistency is less of a concern when producing a single part. | 3 |

| Tool Handling | The ATC may not be necessary for a single part. | 1 | Manual tool changing can be manageable when producing a single part. | 3 |

| Safety | CNC machines come with safety cabinets and the process is automated. | 3 | There’s a risk of injury with manual machining, but for a single part, the risk may be manageable. | 2 |

| Cost Efficiency | The setup time and cost for CNC machines may not be worth it for a single part. | 1 | Manual machines can be more cost-effective for producing a single part. | 3 |

| Total Points | 9 | 20 |

Scenario-4: 3 parts need to be machined with medium-level precision.

| Criteria | CNC Machining | Points | Manual Machining | Points |

|---|---|---|---|---|

| Precision | CNC machining can provide high precision, but medium precision is also achievable. | 2 | Manual machining can achieve medium precision with a skilled operator. | 3 |

| Volume | CNC machining is efficient for high-volume production. For 3 parts, the setup time may still be worth it. | 2 | Manual machining is suitable for small production runs like 3 parts. | 3 |

| Speed | CNC machines can operate continuously without breaks, but the setup time for 3 parts may reduce the speed advantage. | 2 | Manual machining may be slower, but for 3 parts, the difference in production time may not be significant. | 3 |

| Consistency | CNC machines can replicate the same precision across all 3 parts. | 3 | Manual operations may have slight inconsistencies, but for 3 parts, this may not be a major issue. | 2 |

| Tool Handling | CNC machines have an Automatic Tool Changer (ATC) that can handle multiple tools efficiently. | 3 | Manual machining requires manual tool changing, which can be manageable when producing 3 parts. | 2 |

| Safety | CNC machines come with safety cabinets and the process is automated. | 3 | There’s a risk of injury with manual machining, but for 3 parts, the risk may be manageable. | 2 |

| Cost Efficiency | The setup time and cost for CNC machines may be worth it for 3 parts, especially if multiple tools are needed. | 2 | Manual machines can be more cost-effective for producing a small number of parts. | 3 |

| Total Points | 17 | 18 |

Finally, the below table helps with the Type of part that can be machined.

| Type of Part | Best Machining Method |

|---|---|

| High-volume production parts | CNC Machining |

| Complex parts requiring high precision | CNC Machining |

| One-off custom parts | Manual Machining |

| Prototypes | Manual Machining |

| Parts requiring on-the-fly adjustments | Manual Machining |

| Large parts requiring multiple tools | CNC Machining |

| Small production runs | Manual Machining |

7. Conclusion

In conclusion, as you can see CNC Machining and Manuel machining has different strengths and weaknesses. CNC machining, with its precision, consistency, and ability to handle complex designs, has revolutionized the manufacturing industry. On the other hand, traditional machining continues to hold its ground, offering flexibility, control, and a lower barrier to entry.

Please don’t forget, the best machining method is which fits best to your project budget, precision, and volume requirements.