1) Introduction

If you’re as passionate about CNC machining as I am, you’ll know that surface finishes are more than just a final touch. Besides the cathing dimensions of parts, we also fight to catch correct Surface finishing results.

Even the final results are mostly determined by the design engineers, so you can always find information on the blueprints and mechanical drawings about the specific surface quality needs. As a CNC machinist, you are obligated to catch specified surface quality.

Also if you are a mechanical designer you should just select a proper surface finish quality, otherwise unnecessarily increased quality will increase the part`s machining cost. So, let’s dive in and explore the world of surface finishes.

2) What is a Surface Finish?

Surface finishes in CNC machining are more than just a final touch. They are crucial determinants of the part’s performance, affecting everything from corrosion resistance to friction levels. In microscopic level machining tools leaves a mark on the part, surface finish methods should be used to bring this roughness to an acceptable level. We use special cnc machining methods by decreasing scallop heights, feed rates, and vibration.

3) Common Different types of Surface Finishes

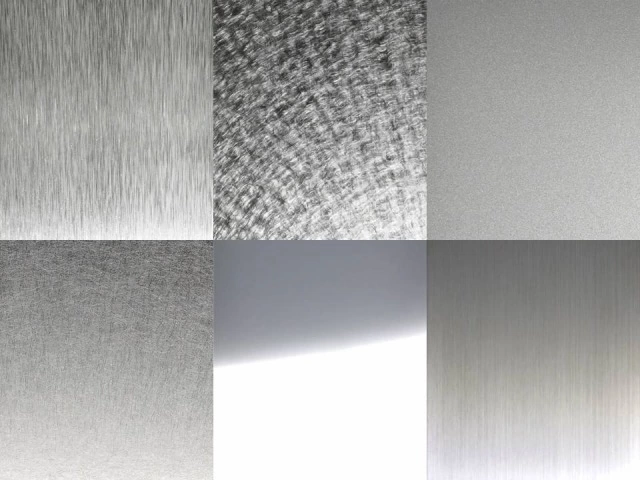

a) Machined Finishes

Machined finishes are natural finishes. They are the result of the machining process itself. Typically, they are characterized by the tool marks left by the cutting tool on the surface of the part. The quality and appearance of a machined finish can vary greatly. The quality of the machining marks depends on diverse machining parameters, including the type of tool used, the feed rate, and also spindle speed.

There are two types of machined finishes: ‘As Machined‘ and ‘Smooth Machined‘.

- As Machined: This kind of finish leaves tool marks that follow the path of the cutting tool. Generally, it is good for reducing costs if tolerances are not tight. With this method 0.1mm-0.25mm (0.003937 inches to 0.00984375 inches) tolerance is achievable.

- Smooth Machined: This kind of finish is achieved by using a finer stepover (which causes smaller scallop height) to reduce the visibility of the tool marks, resulting in a smoother surface. To have a mirror finish you should decrease feedrate and increase spindle speed. But going also with maximum speed can cause vibration-related marks on the machined surface. Very tight tolerances are achievable between 0,02mm-0,05mm (0.0007874 inches to 0.0019685 inches).

Performing a good surface finish with these methods requires a deep understanding of the machining process and careful control of machining parameters.

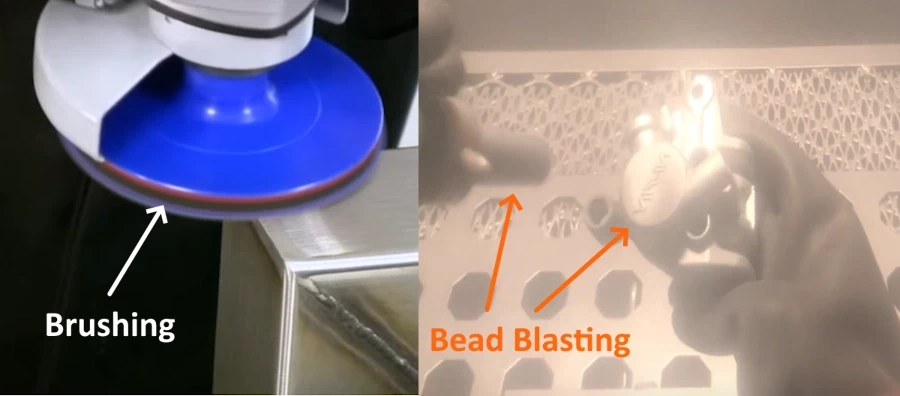

b) Primary Finishes

Primary finishes involve additional processes that mechanically alter the surface of the part to change or remove the machining marks. These finishes can help improve the part’s aesthetic appeal and functionality.

Two common types of primary finishes are ‘Bead Blasting‘ and ‘Brushing‘.

- Bead blasting: involves blasting the part with small glass beads using a pressurized air gun, which removes some material and smooths out the surface.

- Brushing: This method involves polishing the metal with grit to produce a uni-directional satin finish.

c) Secondary Finishes

Secondary finishes involve processes that chemically alter or coat the surface of the part. These finishes can significantly enhance the part’s resistance to wear, corrosion, and other environmental factors.

Two popular types of secondary finishes are ‘Anodizing‘ and ‘Powder Coating‘;

- Anodizing: Anodizing(Type 2 and Type 3) involves submerging the part in a diluted sulfuric acid solution and applying an electric voltage, which converts the surface of the part to hard aluminum or titanium oxide.

- Powder Coating: Powder coating applies a thin layer of protective polymer on the surface of the part.

These finishes can significantly improve the part’s resistance to wear. They can also enhance corrosion resistance.

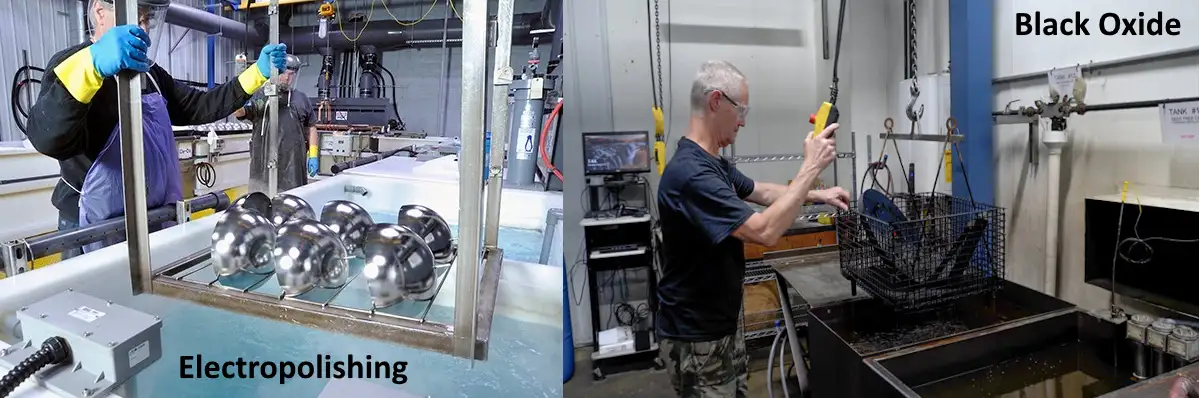

4) Exotic Surface Finishes

There are some uncommon finish techniques used for mechanical part finishing. The most important ones are;

- Electropolishing

- Black oxide

- Electrolytic nickel plating

a) Electropolishing

Electropolishing involves an electrical current and an electrolyte liquid. This liquid and electrical current deburrs sharp edges and removes some material from the very top of the surface. The operation is carried out by submerging the part in electrolyte liquid.

It cleans the parts deeply so it is very good for food handling parts, and medical parts. Corrosion resistance and surface smoothness are achievable very easily with this method. You can hear this process called “Reversal Plating“.

b) Black Oxide

Black oxide is very useful for giving a nice surface finish to ferrous materials like Stainless, Copper. Besides adding corrosion resistance, it gives a nice look to parts. Sodium and hydroxide, nitrate baths cause the chemical reaction to create a black formation on the surfaces of the parts. It is very useful for non-reflective applications like gun parts used in the military.

c) Electrolytic Nickel Plating

Electrolytic Nickel Plating is good for coating and giving a nice finish to conductive material machined parts. Because of the nice corrosion resistance is given by its process, it used often on the parts which work in harsh environments. So it is used widely in the automotive and aerospace industries.

5) Abrasive Surface Finishes

Abrasive surface finishing techniques are very useful for giving a good surface finish to parts.

Some of them;

- Grinding

- Linishing

- Polishing

a) Grinding

Grinding is also considered a machining method because an abrasive grinding wheel is used to deform the surface of the part. These wheels can be manufactured from very fine sands so very high surface quality and dimensional correctness can be achievable.

b) Linishing

The Linishing finishing method requires linishing machines which are compatible with sand belts. This method is suitable for removing intense machining marks from planar surfaces. However, parts are mostly handled by hand, so hand craftsmanship is very important for this category. Different sand particular sized belts can give different surface patterns.

c) Polishing

Polishing is another method to give a nice surface finish to CNC machined parts. This method is more flexible and removes very less material from the surface of the part. It is used mostly in the plastic molding industry due to the mirror surface finish requirements.

6) Tips For Optimal Surface Finish

- Tip-1: On the design documents and drawings openly mention the surface quality for specific surfaces.

- Tip-2: Use proper surface finish symbols to relate the surface.

- Tip-3: Try to reduce surface quality requirements as much as you can, this will reduce part`s cost too.

- Tip-4: Try to avoid coatings and anodizing unless rusting and esthetically looks if not important on the part.

7) Conclusion

In conclusion, surface finishes in CNC machining are very important to job correctly. As you see unnecessary surface finish requirements easily increase the cost of machining. On the other hand, a part with a not-good surface finish can cause a lot of headaches.

So consider the project budget and requirements for parts always. If you involve with designing mechanical parts and generating drawings then make sure you use proper surface finishing symbols and notifications. In this way, CNC machinists will not spend unnecessary time catching unwanted surface finishes. This will decrease the cost of part manufacturing.