Choosing the correct materials is vital for good CNC work, whether you have your own workshop or are outsourcing to a job shop. Material selection happens early in the design process, usually by mechanical designers. As a CNC worker, you’ll often receive materials from suppliers. However, since many CNC job shops also offer design services, it’s important for everyone to understand the right material selection process. Knowing how to pick the right material for the project is very important.

As a CNC machinist and programmer, you need to focus more machinability characteristics of materials rather than designers’ focus on strength and durability. Also, as you are a CNC programmer and machinist, you must give your superior advice to your design team about the materials. For example; you can tell them how you can finish the job faster by machining mild steel instead of a Monel, Titanium material.

- CNC Materials: How To Choose The Right Materials for CNC Machining?

- Materials can be machined with CNC

- Common Metal Materials for CNC Machining

- Common Plastic Materials for CNC Machining

- Machinable Woods With CNC Routers

- Using Standard Extruded Profiles To Increase Efficiency in CNC Machining

- Special And Exotic Materials

- Material Selection Process For CNC Machining

- Material Stock Shape and Its Impact on the Material Receiving Process

- FQA For Material Selection

- Conclusion

CNC Materials: How To Choose The Right Materials for CNC Machining?

I’ve learned over time that choosing materials depends on the part`s required features. It also depends on how they are used and the result you want. Every material has its usage advantages and disadvantages for the project. Aluminum, is favored for its lightweight and easy to cut with CNC cutters, making it a common choice in the aerospace and automotive industries.

Stainless steel, another important engineering material, brings strength and corrosion resistance. Stainless steel is anti-corrosion and very durable. Stainless steel machined components maintain dimensional accuracy even under harsh conditions.

Materials can be machined with CNC

The scope of materials you can use in a CNC machine is vast. Apart from metals like aluminum and steel, plastic use is growing. Polyethylene and PVC are often used in CNC work because they resist chemicals and handle heat well.

Furthermore, Titanium is a super material that is lighter, stronger and can stand against harsh environments like underwater and space radiation. So it is generally used for the Aerospace industry. The CNC world is always changing; we’re learning more about these materials. This leads to better and faster production results.

Keep in mind, that each project is unique. The ‘best’ material depends on your specific needs. Choosing wisely is essential, and I’m here to help you in this exciting CNC journey.

Common Metal Materials for CNC Machining

In my job, I’ve used many different metals, each having special features and benefits.

1. Aluminum

Aluminum 6061 has impressive machinability and strength-to-weight ratio, a staple in both the aerospace and automotive sectors. Aluminum 7075 has superior strength compared to 6061, when durability and lightweight making it an excellent choice. 6000-7000 series aluminum does not stick to the cutting tools in high spindle speeds. Aluminum has a wide range of uses in the aerospace and prototype manufacturing industry.

| Material | Usage For Part Manufacturing |

|---|---|

| Aluminum 6061 | For prototypes and parts in various industries. It offers good strength, corrosion resistance, and excellent machinability. |

| Aluminum 7075 | Aerospace components due to their high strength-to-weight ratio, have excellent fatigue resistance. |

| Aluminum 2024 | Used for CNC machining aircraft parts, thanks to its high strength, and good machinability. |

| Aluminum 5083 | Ideal for CNC machining marine components due to its excellent corrosion resistance and high strength. |

| Aluminum 6063 | Often used in CNC machining architectural profiles and extrusions, provide good formability and surface finish. |

| Aluminum 5052 | Suitable for CNC machining electronic enclosures and panels, offering good corrosion resistance and easy formability. |

2. Brass, Copper, Bronze

Brass is great to use because it machines well, making beautiful, yellow corrosion-resistant CNC machined parts. Generally, Brass and Copper materials are not very strong against large forces.

Therefore, they should not be used for dynamically working parts that are subjected to bending and shearing stress since they cannot withstand such forces. However, Brass and copper-based materials are highly suitable for decorations, musical instruments, plumbing, and even static stationary parts in machinery.

| Material | Usage For Part Manufacturing |

|---|---|

| Brass | CNC-machined brass parts are used in industries where strength, electrical conductivity, and corrosion resistance are needed. Parts include gears, decorative parts, fittings, nozzles, valve parts, and more. |

| Copper | Copper’s excellent conductivity makes it ideal for CNC machining parts in electrical applications. |

| Bronze | Bronze is often CNC machined for bearings, bushings, and other mechanical components. |

| Aluminum Bronze | Good for strength and corrosion resistance make it a good material for heavy-duty mechanical parts. Used in the aerospace oil, and gas industries. |

| Phosphor Bronze | Commonly CNC is machined for electrical components and heavy-duty mechanical parts due to its toughness and fatigue resistance. |

| Tellurium Copper | Used for Electrical connectors and welding tips. |

| Beryllium Copper | Good for electronic connectors, telecommunications products, and computer components. |

| Copper-tin-zinc alloys (Gunmetal) | Similar to brass, it is used in industries requiring strength, electrical conductivity, and corrosion resistance. |

3. Magnesium based

Let’s not forget about Magnesium AZ31, a relatively lightweight metal that offers excellent dimensional stability. It’s a material that can deliver strength without the heft. It is very suitable for casting so automotive motor parts can be made from this material easily with high volume.

| Material | Usage For Part Manufacturing |

|---|---|

| Magnesium AZ31 | For lightweight components in industries such as aerospace, automotive, and electronics. It offers a good strength-to-weight ratio and excellent machinability. |

| Magnesium AZ91 | Commonly used for applications requiring higher strength, such as automotive parts and structural components. It provides good corrosion resistance and weldability. |

| Magnesium AM60 | Used for aerospace, defense, and motorsports. it has an exceptional strength-to-weight ratio and excellent machinability. |

| Magnesium AE42 | Used for applications requiring high-temperature resistance, such as automotive engine parts and transmission cases. It offers good creep resistance and thermal conductivity. |

| Magnesium ZK60 | Sporting goods, aerospace components, and medical devices due to their high strength, good corrosion resistance, and impact absorption capabilities. |

| Magnesium Elektron | They are used for high-performance applications, including aerospace, defense, and motorsports. it has an exceptional strength-to-weight ratio and excellent machinability. |

4. Stainless Steel

In the Stainless range, CNC machinists and mechanical designers generally use 303, 304, and 316, each with its own merit. Stainless Steel 303 is particularly favored in CNC machining for its ease of fabrication.

The 304 variant is known for its corrosion resistance, while Stainless Steel 316 brings superior chemical resistance to the table, perfect for parts expected to weather harsh conditions. Duplex stainless steel is a widely used term in this material group. It refers to incredible maximum corrosion resistance.

| Material | Usage For Part Manufacturing |

|---|---|

| Stainless Steel 304 | Commonly used for a wide range of applications. Kitchen equipment and architectural components are some of them. |

| Stainless Steel 316 | Preferred for components exposed to harsh environments, such as marine and chemical industries. |

| Stainless Steel 420 | Often selected for parts requiring high hardness and wear resistance, such as surgical instruments and cutting tools. |

| Stainless Steel 17-4 PH | Suitable for high-strength and corrosion-resistant components, such as aerospace and oil, and gas equipment. |

| Stainless Steel 303 | Frequently chosen for CNC machining of parts requiring good machinability, such as fittings and bushings. |

| Stainless Steel 316L | They are often used for corrosion-resistant components in medical and pharmaceutical applications. |

| Duplex Stainless Steel | Preferred for applications requiring a combination of high strength and corrosion resistance, such as oil/gas equipment and chemical processing. |

5. Carbon Steel

Carbon Steel 1045 is another essential material, it has high strength and good machinability, a go-to option for many industrial applications.

| Carbon Steel Classification | Carbon Content-Range | Characteristics |

|---|---|---|

| Low Carbon Steel | 0.05% – 0.25% | Good machinability, weldability, and ductility. |

| Medium Carbon Steel | 0.25% – 0.60% | Balances strength and ductility for various applications. |

| High Carbon Steel | 0.60% – 1.00% | Excellent strength and hardness with lower ductility. |

| Material | Usage For Part Manufacturing |

|---|---|

| Carbon Steel 1018 | Widely used for various applications, including shafts, gears, bolts, and general-purpose parts. It offers good machinability and moderate strength. |

| Carbon Steel 1045 | Parts that require excellent machinability and good strength, such as threaded components, studs, and bolts. |

| Carbon Steel 1080 | Widely used for various applications, including shafts, gears, bolts, and general-purpose parts. It offers good machinability. |

| Carbon Steel 1144 | Parts that require excellent machinability and good strength, such as threaded components, studs, and bolts. |

| Carbon Steel 12L14 | Parts that require excellent machinability and good strength, such as threaded components, studs, bolts. |

| Carbon Steel 5160 | Commonly used for CNC machining applications requiring high strength and durability, such as automotive leaf springs and agricultural equipment parts. |

| Carbon Steel 1020 | Often preferred for general-purpose parts, such as brackets, couplings, and fittings. It offers good weldability. |

6. Titanium and its grades

Of course, there’s Titanium which is a powerhouse. It has strength, lightness, also exceptional temperature resistance. It’s challenging to machine but yields unparalleled results, particularly in the aerospace industry. Also, its price generally is higher than general-purpose materials.

| Titanium Alloy | Typical Applications |

|---|---|

| Grade 1 (CP-1) | Chemical processing, aerospace, marine |

| Grade 2 (CP-2) | Heat exchangers, piping systems |

| Grade 5 (Ti-6Al-4V) | Aerospace components, automotive, medical |

| Grade 7 (Ti-0.2Pd) | Chemical processing, seawater applications |

| Grade 9 (Ti-3Al-2.5V) | Aerospace, marine, chemical processing |

| Grade 23 (Ti-6Al-4V ELI) | Medical implants, surgical instruments |

| Grade 12 (Ti-0.3-Mo-0.8Ni) | Chemical processing, desalination, marine |

Common Plastic Materials for CNC Machining

Plastic materials are known for their lightness and easy-to-machine properties. Their thermal expansion ratio can be used as an advantage for some applications, but also can always you need to watch for expansion. Plastic sheets generally can be cut with CNC Routers and CNC Lasers. With this method, a lot of small parts can be cut from a large plastic sheet thanks to the help of nesting CAM software. The below table shows the most common plastics and their usage area.

| Plastic | Properties | Common Applications |

|---|---|---|

| ABS (Acrylonitrile Butadiene Styrene) | Durable, impact-resistant, lightweight. | Prototyping, end-use parts, automotive trim, electronic housings. |

| Nylon | Excellent transparency, and good machinability. | Automotive components, gears, bearings, consumer products. |

| PMMA Acrylic (Plexiglass) | Exceptional chemical resistance, and high-temperature stability. | Windows, lenses, displays, signage, light fixtures. |

| PEEK (Polyether Ether Ketone) | Aerospace components, automotive parts, and medical implants. | Aerospace components, automotive parts, medical implants. |

| UHMWPE (Ultra-High-Molecular-Weight Polyethylene) | High strength, wear resistance, low friction. | Bearings, gears, conveyor components, lining materials. |

| PVC (Polyvinyl Chloride) | Versatile, cost-effective, good chemical resistance. | Pipes, fittings, electrical insulation, signage, flooring. |

| Delrin (Polyoxymethylene) | Excellent mechanical properties, low friction, high stiffness. | Gears, bushings, valves, electrical components, automotive parts. |

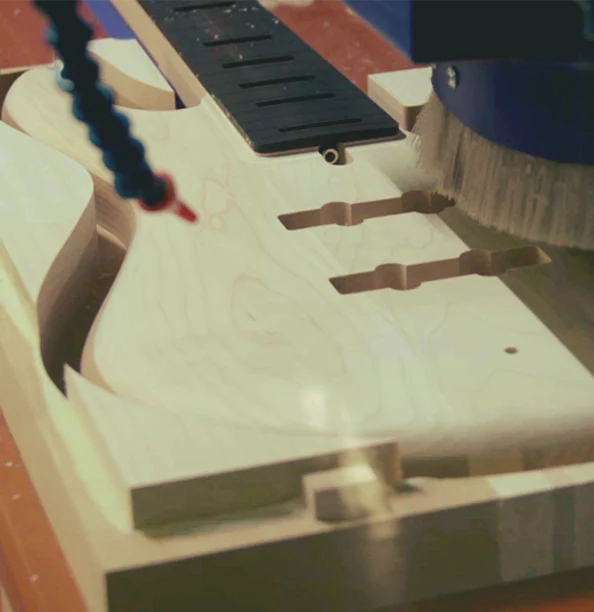

Machinable Woods With CNC Routers

These days wood machining is very common for hobbyists and cabinet makers. Musical instrument manufacturers use CNC Routers to cut out complex guitar shapes from wood. That kind of part manufacturing requires dust collection vacuum systems.

| Wood | Common Applications |

|---|---|

| Maple | Furniture, cabinetry, flooring, musical instruments |

| Oak | Furniture, flooring, cabinets, interior trim |

| Walnut | High-end furniture, cabinetry, flooring, decorative accents |

| Cherry | Fine furniture, cabinetry, millwork, decorative applications |

| Mahogany | High-quality furniture, millwork, interior trim, musical instruments |

| Birch | Furniture, cabinetry, millwork, plywood, interior applications |

| Pine | Construction, interior trim, furniture, crafts |

| Cedar | Outdoor applications (siding, decking, fencing) |

| Ash | Furniture, cabinetry, tool handles, sports equipment |

| Bamboo | Flooring, furniture, paneling, decorative items |

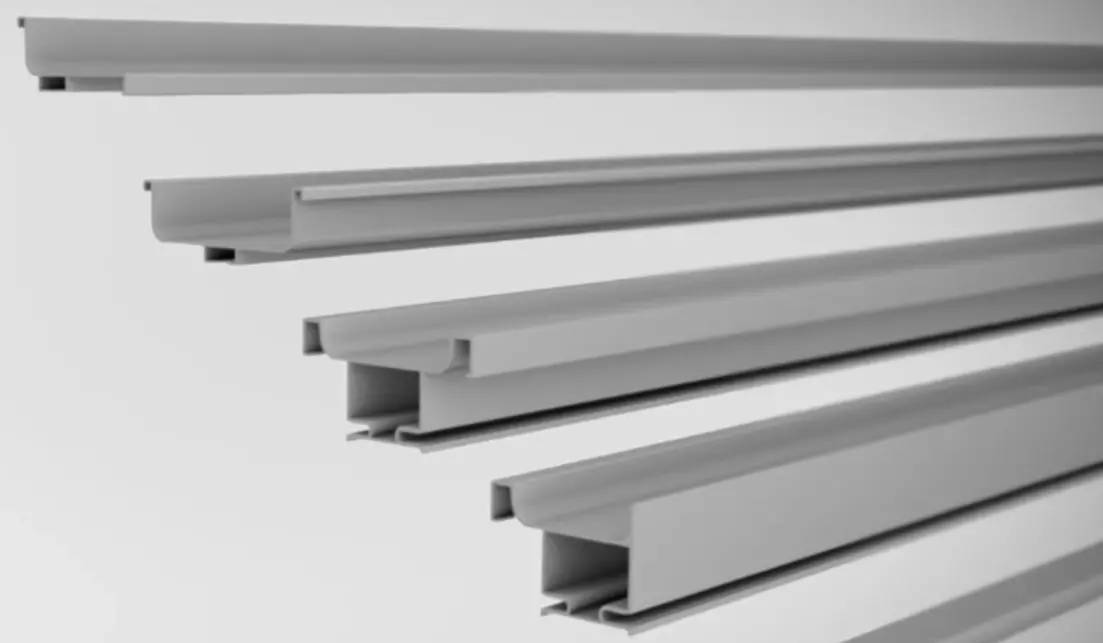

Using Standard Extruded Profiles To Increase Efficiency in CNC Machining

The key advantage of standard profiles is their ability to optimize material efficiency. Unlike starting from raw material blocks, standard profiles require less machining and generate minimal waste. This saves time and reduces material costs.

Different materials provide a range of options. Aluminum profiles offer lightweight construction, corrosion resistance, and excellent machinability. Steel profiles provide strength and durability. On the other hand plastic profiles, such as nylon or PVC, offer versatility and cost-effectiveness.

Standard profiles provide you with a way to quickly design mechanical chassis and frames. The best thing all standard extruded profiles have dimensional catalogs and 3D models, so you can easily use them in your CAD/CAM software simply by importing them. By using pre-formed shapes made from various materials, CNC machinists can give better prices to their customers.

Special And Exotic Materials

Exotic materials are generally expensive because they are manufactured very limited to solve very specific problem.

| Material | Key Properties | Common Applications |

|---|---|---|

| Inconel | High heat and corrosion resistance, strength at high temperatures. | Aerospace, marine applications. |

| Monel | Excellent anti-corrosion properties, particularly in seawater. | Marine applications. |

| Hastelloy | Exceptional strength and heat resistance, suited for aggressive environments. | Chemical processing plants, high-temperature industries. |

| Tungsten | High density, hardness, and temperature resistance. | Aerospace, automotive, and other high-temperature uses. |

| Carbon Block | Exceptional strength, thermal, and electrical conductivity. | Aerospace, automotive, electronic instrument manufacturing. |

| Ceramic | Thermal resistance, electrical insulation. | Electronics, medical equipment. |

Material Selection Process For CNC Machining

Choosing the right material block or round bar for CNC work is key to getting the result you want. You can find in below some guiding questions to assist you in making the best choice:

Essential Questions and Considerations for Selecting the Right CNC Material:

- What Is the Project Cost Budget? The project budget plays a significant role in the material selection. Materials like aluminum and plastics tend to be more affordable than exotic materials such as titanium or carbon blocks. Remember that machining costs, material costs, and post-processing costs all factor into the overall project budget.

- What Is the Machine Stability? The stability of the CNC machine is very important. Unstable machines can result in imprecise parts and higher scrap rates. Ensure that the chosen material can be machined reliably with your available equipment.

- Is the Machine Available? Machine availability is another critical factor. Even if a material is perfect for your part, if the required machine is not available when needed, it can lead to delays in your production schedule.

- How Will the Part Be Used? The intended application of the part will largely determine the type of material required. For example, a component designed for an aerospace application may need a material with high strength and temperature resistance, like titanium.

- Will the Part Be Used Outdoors or Indoors? Outdoor components often require materials that are resistant to environmental conditions, such as UV radiation, and moisture. Stainless steel 316, for instance, is known for its excellent corrosion resistance.

- What Is the Part Delivery Time? The lead time or delivery time for the machined parts depends on the complexity of the parts, the machinability of the material, and the workload of the CNC shop. Some materials can be machined more quickly than others, which can help meet tight deadlines.

- What Is the Material’s Stress Load? The load or pressure that a part will bear is a crucial factor. Materials like carbon steel 1045 can withstand high-stress loads, making them suitable for such applications.

- What Is the Material’s Dimensional Tolerance? Tolerance dictates the precision of your CNC parts. For instance, aluminum is favored for its machinability, often yielding parts with high dimensional accuracy.

- Material finishing operations? After a part has been machined, it may undergo additional processes to enhance its functionality or aesthetics. These post-machining operations often involve applying a surface finish or a protective layer to the part, such as coating or anodizing and surface polishing.

- What Is the Required Fastening? Depending on how a part will be assembled or fastened, you may need a material that can handle specific joining techniques, like welding or adhesives.

- What Are the Operating Temperatures? The working temperature range of the part should be considered. If it’s going to be subjected to high temperatures, materials with excellent heat resistance, such as Inconel, could be ideal.

- What Are the Weight and Stress Capacity? The maximum weight and stress capacity of a material can determine its suitability for certain applications. Lightweight metals like aluminum and magnesium are often preferred in industries like automotive and aerospace where weight reduction is crucial.

Tips on how material selection can make CNC machining easier, safer, and more cost-effective.

- Tip 1 – Machinability Matters: When selecting materials for CNC machining, prioritize those with good machinability. Opt for materials like aluminum and certain plastics known for their excellent machinability characteristics. As a result, machining time is reduced, and efficiency is increased.

- Tip 2 – Safety First: Consider the safety aspects associated with the materials you choose. Look for materials that offer good safety features, such as low toxicity or reduced risk of producing harmful fumes or particles during machining.

- Tip 3 – Cost Considerations: Material selection can significantly impact the overall cost of CNC machining. Evaluate the cost-effectiveness of materials based on availability, price, and waste reduction potential. Choose readily available and reasonably priced materials to control costs. Additionally, selecting materials that minimize waste through efficient machining processes contributes to cost savings.

- Tip 4 – Compatibility with Equipment: Ensure the materials selected are compatible with your CNC equipment and tooling. Consider factors such as the cutting tools required, machine capabilities, and the material’s hardness or toughness. Compatibility between materials and equipment improves machining performance, reduces tool wear, and prevents unnecessary damage to the machinery.

- Tip 5 – Application-Specific Considerations: Tailor material selection to the specific application requirements. Opting for easily accessible and affordable materials can contribute to cost control.

- Tip 6 – Consult with Suppliers and Peers: Seek advice and expertise from material suppliers and experienced peers in the CNC machining field.

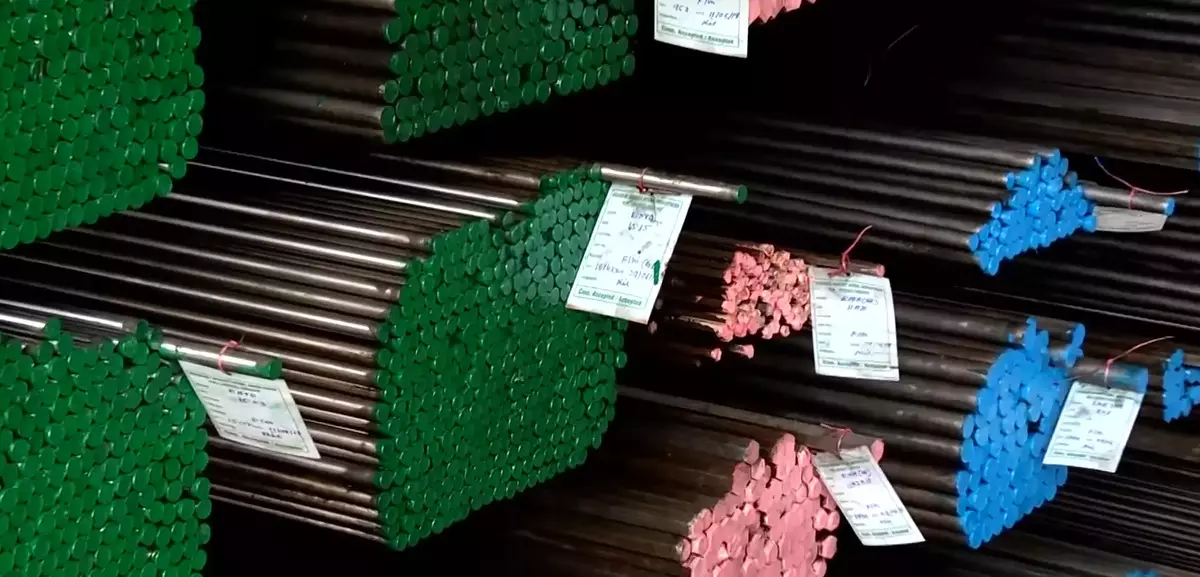

Material Stock Shape and Its Impact on the Material Receiving Process

In the industry of CNC machining, the material procurement process is closely intertwined with the concept of material stock shape. As CNC machinists, we are accustomed to working with precisely shaped blocks and round bars rather than dealing with raw ores or unprocessed materials.

By leveraging standardized stock shapes like rectangular blocks and cylindrical rods, CNC machinists can optimize their workflow seamlessly. It is important to acknowledge that material stock shapes undergo specific manufacturing processes to attain the desired dimensions and surface finish.

With material stock shapes readily available, CNC machinists can focus their expertise on programming and tooling, knowing they have a reliable foundation for their work. An un-uniform stock cannot be easily held by wises and chucks. So, clean straight 90-degree cornered block shapes and standard diameter round bars make CNC machinist life easier and guarantee cheaper operation costs.

Working closely with material suppliers, CNC machinists consider factors such as material availability, cost-effectiveness, and desired machining outcomes.

FQA For Material Selection

What is Aluminum?

Aluminum is a light, durable, and economically viable alloy. It machines well and has a good balance of strength and weight, which is why it’s often used in the aerospace and car industries.What is Stainless Steel?

Stainless Steel is a tough, long-lasting alloy famous for its strength and rust resistance. It’s versatile and widely used in everything from cookware to the manufacturing sector due to its longevity and aesthetic appeal.What is Mild Steel?

Mild Steel is a versatile alloy characterized by its malleability and weldability. It’s a general-purpose metal used in various applications, from construction to automotive, due to its good machinability and strength.What is Alloy Steel?

Alloy Steel is a variant of steel that has been mixed with other elements to enhance its properties, such as increased toughness, hardness, and wear resistance. It’s commonly used in high-stress applications where durability is critical.What is Tool Steel?

Tool Steel is an extremely tough alloy that is highly resistant to abrasion and deformation. It’s primarily used to make tools that need to withstand significant wear and tear, such as drills and dies.What is Brass?

Brass is a highly conductive and aesthetically pleasing alloy made from copper and zinc. Its attractive appearance and excellent machinability make it ideal for decorative pieces and electrical components.What is ABS?

ABS, or Acrylonitrile Butadiene Styrene, is a common thermoplastic known for its toughness and impact resistance. It’s often used for prototyping and producing durable parts and components.What is Nylon?

Nylon is a popular engineering thermoplastic, known for its strength, wear resistance, and flexibility. It’s widely used in many industries, from clothing to car parts.What is Polycarbonate?

Polycarbonate is a durable thermoplastic known for its exceptional impact strength and transparency. It’s commonly used in applications requiring clear, robust materials, like eyewear and windows.What is POM (Delrin)?

POM, also known as Delrin, is a highly machinable plastic. Its hardness, precision, and dimensional stability make it a popular choice for producing precision parts.What is PTFE (Teflon)?

PTFE, often known by the brand name Teflon, is a thermoplastic known for its high-temperature resistance and low friction. It’s often used in applications that involve heat and sliding movements.What is HDPE?

HDPE, or High-Density Polyethylene, is a durable and lightweight thermoplastic. It’s highly resistant to impact and weather conditions, making it an excellent choice for outdoor applications and piping systems.What is PEEK?

PEEK, or Polyether Ether Ketone, is a high-performance plastic known for its strength, chemical resistance, and ability to withstand high temperatures. Its impressive properties make it a viable alternative to metal in many applications.Conclusion

As you see there are a lot of material options to manufacture your parts and projects. Selecting the correct materials has a direct effect on the part`s(project) final cost and the success of the project.