CNC Programming: Mastering G00 and G01 G-Codes

G-code is a fundamental aspect of CNC programming, serving as the language that instructs a CNC machine on how to operate. In this guide, we’ll delve into two essential G-code commands used in CNC machine operation: G00 and G01.

Before starting, if you need some more information about G-Codes check our other articles too;

Tapping With CNC Machine | With G84, G74, G99, G98

G00: Rapid Positioning in CNC Programming

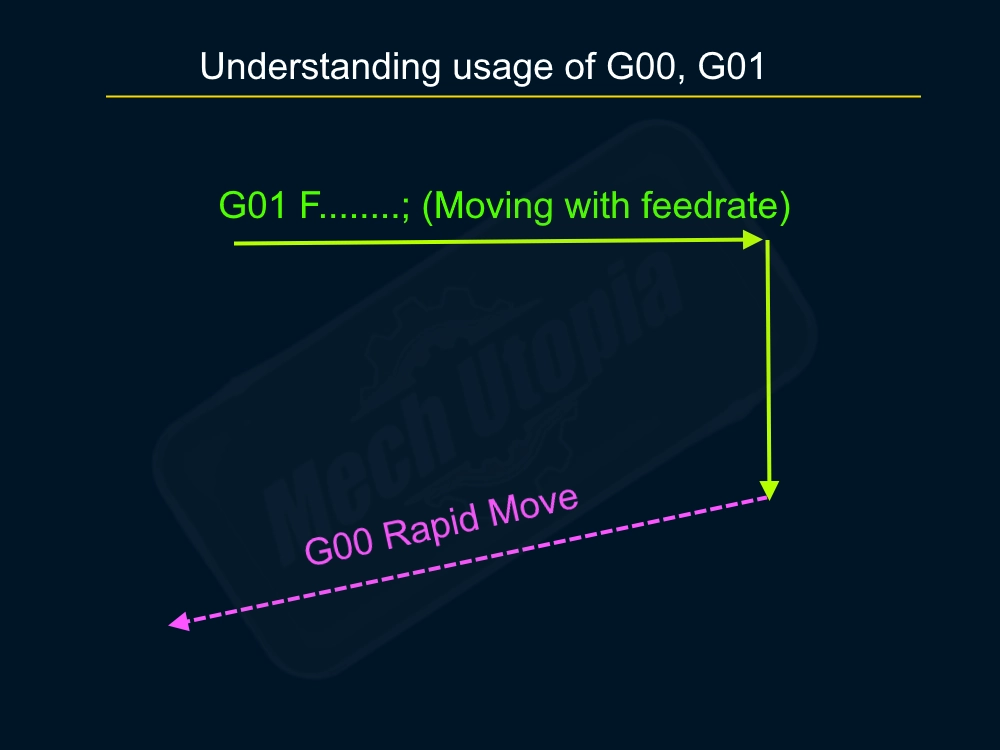

The G00 command, a key component of CNC machine programming, enables rapid positioning of the tool on the workpiece. This command is crucial for efficient CNC machine control, allowing the tool to move quickly to a specified point. However, due to its speed, the G00 command is less precise than the G01 command and should not be used while the cutter work on the workpiece.

This is how the command should look like;

G00 X… Y… Z…

Absolute

G90 G00 X150.0 Z100.0

X200.0 Z200.0

Incremental

G91 G00 X150.0 Z100.0

X200.0 Z200.0

When the G00 command is used, no chip is taken out. It moves as fast as it can on the axes where this G code is written. Values that start with F are not used. The manufacturer sets the G00 speed, which is often stored in the control as a “machine constant variable “. It depends on the speed and power of the machine. This speed is generally fixed by the manufacturer and it is the maximum safe speed the machine can move.

G01 (Linear cutting with feed rate)

Another vital command in the realm of CNC programming techniques is the G01 command. This command, known as linear cutting with feed rate, guides the tool in a straight line to a defined position at a certain feed rate.

Unlike the G00 command, the G01 command is used during the cutting process, allowing for precise control over the tool’s movement and speed.

When the G01 command is used in program lines one after the other, it doesn’t need to be used in any other lines which are following right away. This mode (G01) will stay the same until the commands G00, G02, G03, or cycle are used. The G00 command works the same way.

F: It is the feed rate, and you can choose mm/min or mm/revolution as the unit. If the program uses G99, the feed unit is mm/rev. If G98 is chosen, mm/min. means that it should be used.

Practical Examples of G00 and G01 in CNC Programming

Absolute

G90 G01 X150.0 Z100.0 F0.2 :

Incremental

G91 G01 X10. Y10.

G01 Program (example – 1)

Conclusion: Mastering G00 and G01 for Effective CNC Programming

Mastering G00 and G01 commands is crucial for effective CNC programming and optimizing CNC machine operation. By understanding these commands, you can improve your CNC code generation process and enhance the overall performance of your CNC machine. Whether you’re a seasoned machinist or a beginner in the field of CNC machining, these commands are fundamental to your success.