What is Grooving?

The grooving operation allows us to machine circular channels on cylindrical part surfaces. These channels may be desired to be machined for various reasons. In this article, we will explain how to open channels with the grooving operation in a manual and CNC lathe. We will also learn how to adapt the operation to different groove types.

For example; The circlip grooves can generally be used to fix the bearings in a certain position on the cylindrical surface. At the same time, these channels are needed for part`s security reasons. Also, these grooves are used by engineers during design to ease the lubrication of rotating parts.

You can open these channels not only on cylindrical surfaces but also on the forehead of the cylindrical piece (face grooves).

What are the different types of grooving operation?

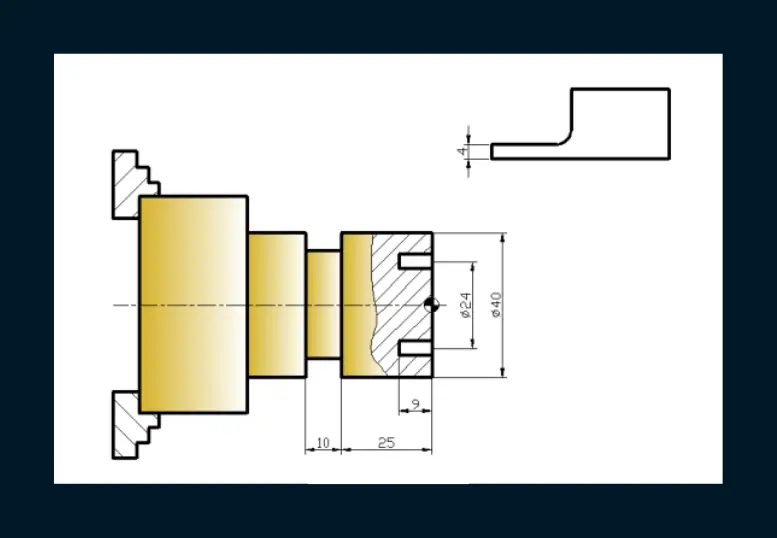

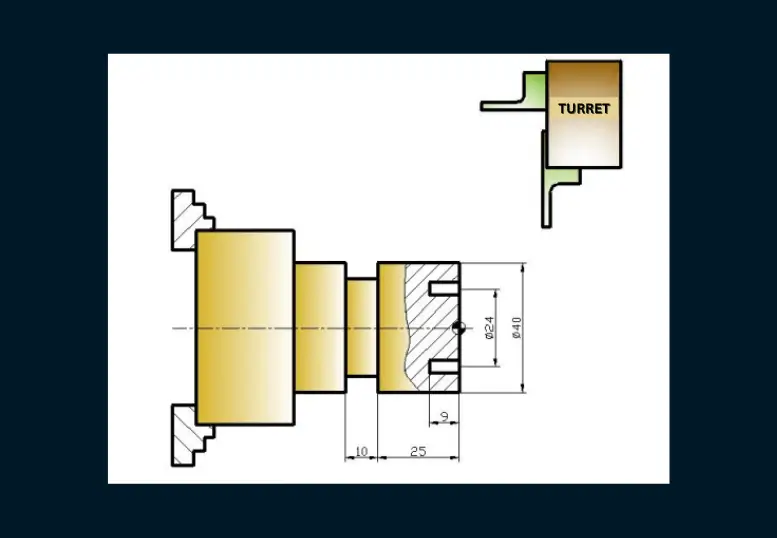

There is three types of grooving operation to machine channels on cyrindirical, forehead surface of the part.1) OD(outer-diameter): It is used to open the grooves to the outer cylindrical surface.

2) ID(Inner-diameter):It is used to open the grooves to the inner cylindrical surface.

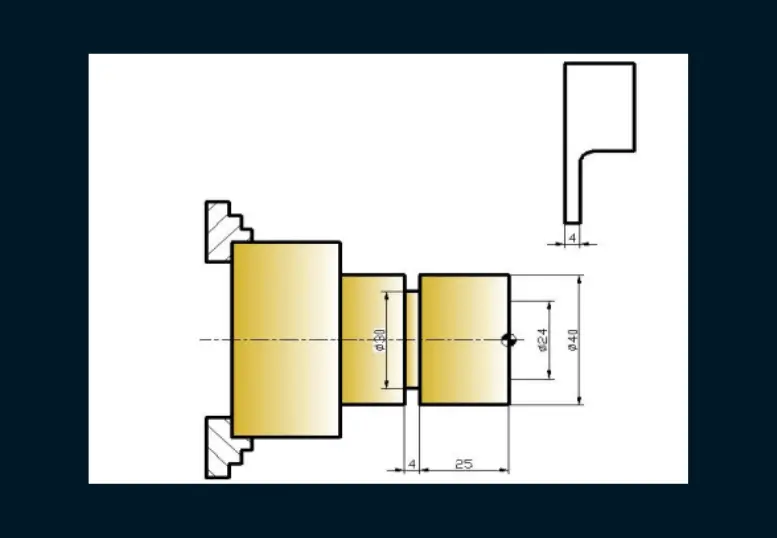

3) Face Grooving: It used for machining grooves to forehead surface of the part

CNC Lathe Grooving Program

In the CNC lathe, the groove can be opened using the G01 command with the groove pen. After determining the most suitable number of revolutions and advanced amount for grooving, the part where the grooving will be opened is approached with rapid (G00) progress. With the G01 command, the cutting tool plunges into the groove. Grooving to the periphery is achieved by moving in the X axis as in face turning.

In the CNC lathe, a channel can be opened on the cylindrical surface as well as on the forehead of the part. An appropriate grooving cutting tool must be used for face grooving.

Manual Programming

The set of commands used for manufacturing parts in CNC machine tools is called a part program. Part programs can be written in alphabetical, numeric, alphanumeric, etc. formats that the machine tool can understand. The feature of the part program is that it consists of commands that the CNC machine can understand and is written in a certain logical order from the beginning to the end.

Command Line:

N_ G01 X_ Z_ F_;

- Fanuc programming

- Siemens programming