Introduction

Metals used in engineering are extremely significant to the development of modern technologies. In this post, we will introduce you to twenty various Metals, all of which can be utilized in the machining process and the production of CNC parts. Also, You will find ISO material group symbols and notations on related material classes.

What are the two main types of metals?

Metals are classified as ferrous or non-ferrous. Ferrous metals contain iron (carbon steel), whereas non-ferrous metals do not (Brass, Bronze, Aluminum, etc).In the below table, you can see materials mentioned in this article with properties like expensiveness, density, and melting point.

What are the 5 basic metals?

Iron, copper, lead, nickel, tin, and aluminum are the most basic materials used almost everywhere.Types of Metals In A Nutshell

As technology improves, production costs are getting cheaper, but the prices of raw materials are going up. We need detailed information about the materials for our designs to be as efficient as we need them to be. In this blog post, we talk about the types of metals used in engineering in a manufacturing-focused way.

The most common type of material used in engineering is metal due to its hardness. People often use metal alloys, which are made by mixing one metal with more metals or non-metals. The main goal of making an alloy is to change the properties of the material in a way that the maker wants.

Before deep diving into the metals world, we strongly recommend having some knowledge about engineering materials’ health and safety prospects. This article gives some information about it. The handling of heavy metals in workshops will be discussed in another article.

ISO material symbols and grouping can be helpful to identify types of materials. As a bonus, we also gave some tips and facts in a table like density, melting point, machinability, and cutting tips. Check the table below;

| Symbol | ISO Material Symbol | Melting Point(°C) | Density(g/cm3) | CNC Machinability-Durability | Advised Cutting Tools | Machining Tips | |

|---|---|---|---|---|---|---|---|

| Iron (Steels) | Fe | P | 1538 | 7.874 | Medium to High CNC Rigidity Required | Carbide End mills ,Carbide & HSS Drills | Can be machined easily with high speed machining. |

| Aluminum | Al | N | 660.3 | 2.70 | Basic to Medium CNC Rigidity Required | HSS Drills & Uncoated Carbide End mills | Easy, high speed machining, Use a lot of coolant to prevent jamming. |

| Copper | Cu | N | 1085 | 8.96 | Basic to Medium CNC Rigidity Required | HSS Drills & Uncoated Carbide End mills | Easy, high speed machining, machining without coolant preferred. |

| Stainless Steel | Fe | M | 1400 ~ 1530 | 7.5 ~ 8 | Medium to High CNC Rigidity Required | Carbide End mills ,Carbide Drills | Hard to machine, Less pass low cutting speed preferred. Coolant on need. |

| Titanium | Ti | S | 1668 | 4.5 | High CNC Rigidity Required | Special tools designed to cut titanium | Very hard to machine , so very less passes and low cutting speed preferred with coolant. |

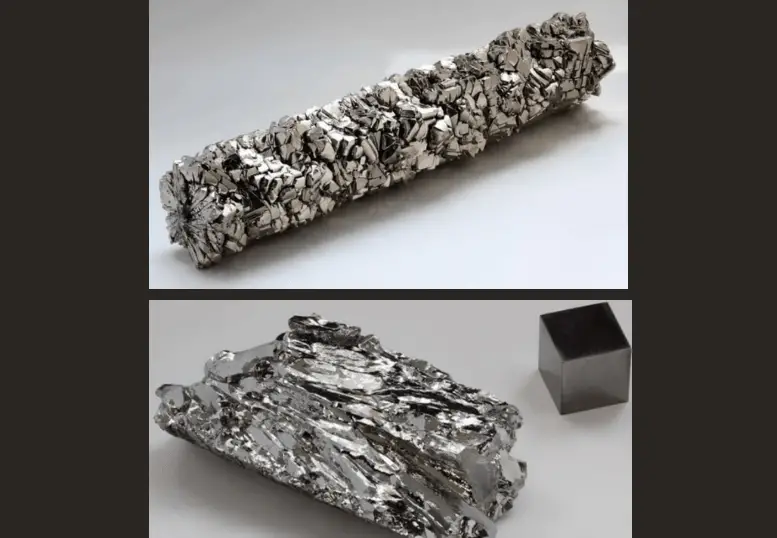

Iron

Iron, a dense metal, is formed through nuclear fusion processes in which lighter elements undergo reactions to create heavier elements, including iron.

It is the most abundant element in the Earth’s crust, accounting for a significant portion of its composition. The production of iron metal requires the extraction and processing of iron ore.

In its purest form, iron is a rare find in nature and typically occurs as an alloy with carbon. Heating iron and carbon to high temperatures creates a liquid alloy, commonly known as cast iron or pig iron.

Iron comprises approximately 96.5% of its composition, with the remaining 3.5% being carbon.

Iron is a heavy metal with a density of 7.87 g/cm³ (0.284 lb/in³) and a melting point of 1538°C (2800°F). At room temperature, iron has a thermal conductivity of 80.4 W/mK and an electrical conductivity of 10.0 MS/m. Aluminum`s Young’s modulus is 211 GPa, while its tensile strength ranges from 350-550 MPa depending on the specific alloy composition and heat treatment. The hardness of iron is typically 30-80 (Brinell Hardness) depending on the specific alloy composition and heat treatment.

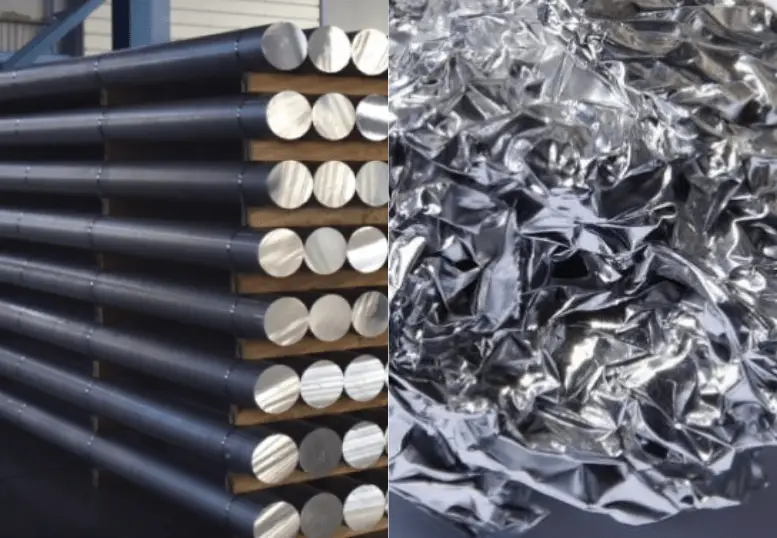

Aluminum

Is it spelled aluminum or aluminium?

It depends on the country and language. The U.K. spells it “Aluminium,” while the U.S. spells it “Aluminum.”Aluminum is a lightweight, corrosion-resistant material that is widely available worldwide. It can be easily molded when hot or cold due to its high malleability.

Anodizing, an electrochemical process, can give aluminum a range of colors and prevent rust formation. Pure aluminum coatings can also be applied to complex alloys to reduce rusting.

Extrusion is a process used to create intricate aluminum profiles, while thin foils are used for packaging. By combining with other elements, aluminum can increase its strength and gain new properties.

Aluminum thick plates and thin sheets give an opportunity to implement it in a wide range of are from mechanical part manufacturing to decoration.

Machining low-grade aluminum can cause sticking to cutting tools, requiring coolants to prevent this, while certain series of aluminum, such as 2000, 5000, 6000, and 7000 series, can be easily machined without sticking. This saves time and resources in CNC machining.

Aluminum has a melting point of 660.3°C (1220.5°F) and a density of 2.7 g/cm³ (0.098 lb/in³). At room temperature, aluminum has a thermal conductivity of 237 W/mK and an electrical conductivity of 37.7 MS/m. Aluminum’s Young’s modulus is 70 GPa, while its tensile strength ranges from 40-90 MPa depending on specific alloy composition and temper. Its hardness ranges from 30-50 (Brinell Hardness) depending on specific alloy composition and temper.

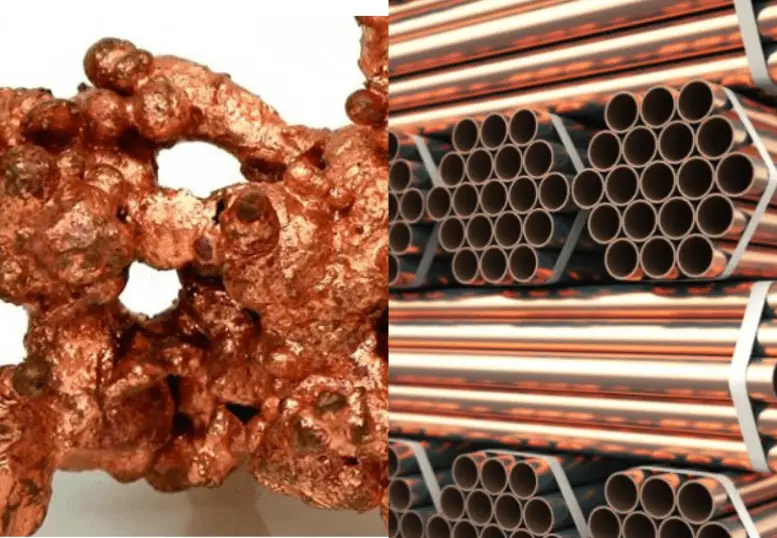

Copper

Which is more stronger? Copper or Steel?

Steel is much stronger than copper, and copper is a softer material and easy to machine and change its shape by applying force.Copper has strong heat conductivity in addition to electrical conductivity. This makes it valuable in applications like heat exchangers and pipes for hot water and steam since it can transport heat rapidly and effectively.

A significant part of many alloys, including brass and bronze, contains copper. To make bronze, add tin, and to make brass, add zinc to copper. These alloys vary from pure copper in that they have higher strength and harder surfaces.

Large open-pit mines and underground mines are used to extract copper. United States, Chile, Peru, China, and China are the top four producers of copper. After being mined, copper is usually purified and formed into a variety of shapes, including wire, tubing, and sheets.

While copper is a precious and useful metal, its usage and manufacture may have a detrimental influence on the environment. For instance, the extraction of copper may pollute the land and water, and the manufacture of copper goods can emit glasshouse gases. As a result, initiatives are being taken to lessen the environmental effect of copper production and consumption, including the use of recycling and alternative energy sources.

Copper has a melting point of 1085°C (1985°F), and a density of 8.96 g/cm³ (0.323 lb/in³). At room temperature, copper has a very high thermal conductivity of 401 W/mK and the highest electrical conductivity of all non-precious metals, measuring 58.0 MS/m. Copper also has Young’s modulus of 130 GPa and a Vickers hardness of 369 MPa. The tensile strength of copper ranges from 200 to 250 MPa, depending on the specific alloy composition.

Magnesium

Due to its many advantages, magnesium is crucial in many sectors. Its benefits make it popular in supplements and therapies. The construction and transportation industry uses it because of its low density and weight. Magnesium’s oxide and carbonate layer prevents corrosion, making it perfect for outdoor use.

Mixing magnesium with other metals improves its mechanical qualities. The aerospace and automotive sector use it. Cast iron and uranium salt need magnesium.

Magnesium reduces oxides to make titanium, zirconium, uranium, and beryllium. Magnesium is widely used to make fuel-efficient, lightweight, and environmentally friendly cars.

Magnesium has a melting point that ranges from 650°C to 1090°C (1202°F to 1994°F), depending on the specific alloy composition. The density of magnesium is generally between 1.74 g/cm³ to 1.83 g/cm³ (0.063 lb/in³ to 0.066 lb/in³), depending on the specific alloy composition as well.

Steel

What is steel made of?

Steel is a mixture of Iron ore and carbon. The percentage of (0.2% to 2.1%) carbon creates different types of steels in terms of softness, strength, and machinability.Due to its exceptional mechanical qualities it has, steel is a significant material in a wide variety of sectors. Because of its high strength, excellent ductility, and ability to be bent in a variety of ways, it is adaptable enough to be used in a wide variety of applications.

The amount of carbon present in steel alloys is a significant factor in determining the material’s strength as well as other properties. Carbon is an essential component in the production of steel alloys.

While carbon is the element that is used to make alloys with iron the most often, other elements such as chromium, tungsten, vanadium, and magnesium may also be used to make alloys with iron.

Engineers and designers are given a wide variety of alternatives to choose from thanks to the fact that the characteristics of these alloyed steels vary depending on the application.

Carbon Steel

Carbon steels consist mostly of iron and carbon, with small amounts of other elements. The carbon content typically ranges from 0.05% to 2.1%, with higher carbon content resulting in greater strength and hardness.

Carbon steels can be divided into two categories: untreated and treated. In machining operations such as lathing and CNC machining, carbon steels are typically worked on at slower speeds due to their hardness.

Most of the parts in the Mechanical engineering industry are machined with carbon metals. They are not corrosion-resistant but their cheapness and machining quality makes them perfect for most mechanic applications. Treating and coating give some corrosion resistance but also make it more brittle.

Carbon steel typically has a melting point that ranges from 1420°C to 1520°C (2588°F to 2768°F), depending on the specific composition of the alloy. The density of carbon steel is generally between 7.85 g/cm³ to 7.87 g/cm³ (0.284 lb/in³ to 0.285 lb/in³), depending on the specific composition.

Alloy Steel

The alloy steel category is the top one for alloyed steel. It is possible to tailor alloy steel to have certain features, such as improved strength or resistance to corrosion, because of the material’s adaptability and versatility.

When combined with other elements, iron, and carbon may be used to produce one-of-a-kind alloy compositions with qualities that are specifically suited to a variety of uses. In order to improve the qualities of steel, in addition to nickel and copper, alloying metals such as manganese, chromium, and molybdenum are often added to the material.

Because of their high levels of strength and toughness in addition to their relatively low cost, alloy steels find widespread use in the industrial sector. Alloy steels can be heat treated so after machining while it fost and hardening later is a common practice in the industry.

In order to make alloy steels more resistant to wear and tear, it is usual practice to subject them to the heat treatment known as quenching.

Stainless Steel

Stainless steel is an alloy made from iron, carbon, and chromium. Because of chromium, it has a shiny appearance. It is a hard material to machine and can stick to cutting tools easily. It has perfect corrosion resistance so widely used in ship manufacturing and medical tool making. Also, it is the most common material used in mechanical part manufacturing after carbon steels.

Is stainless steel stronger than steel?

In fact, it depends on the mixture of the material. In industry, stainless steel is generally stronger than standard carbon steel in terms of corrosion resistance, but standard steel is stronger in durability for most mechanical parts.Does stainless steel rust?

Stainless steel resists corrosion well. Air and acid may corrode low-chromium stainless steels.You can find our stainless steel machining guide in this post.

Stainless steel has a melting point that ranges from 1370°C to 1510°C (2500°F to 2750°F), depending on the specific grade of the alloy. The density of stainless steel is generally between 7.75 g/cm³ to 8.05 g/cm³ (0.280 lb/in³ to 0.291 lb/in³), depending on the specific grade.

Titanium

Since the 1960s, titanium has been used in many products. Reverend William Gregor, an English chemist, made the first discovery and separation. German scientist Martin Heinrich Klaproth gave the element the name “titanium,” naming it after the Titans, the progeny of the Greek earth goddess.

Although being found in the late 1700s, titanium didn’t start to be employed in the aircraft sector until the late 1940s owing to challenges in isolating the metal. Because of technological improvements, it is employed in many different applications nowadays.

In comparison to many other elements, titanium is a precious and uncommon substance with outstanding physical and chemical qualities. Processing may, however, be time-consuming and costly.

Its capacity to adhere to human flesh and bones is one of its most impressive qualities, making it a popular substance in healthcare and medicine. It is often used in the production of automobile and aircraft components.

Is titanium stronger than steel?

Titanium is a much more durable and lightweight material that is very resistant to corrosion, but steel is cheaper in terms of price.The melting point of titanium is around 1668°C to 1670°C (3034°F to 3038°F). The density of titanium is approximately 4.5 g/cm³ (0.163 lb/in³).

Bronze

The same thing is also called bronze metal. It is a type of metal made up of copper and tin. Pure copper doesn’t happen very often in nature. It is usually found in ores like chalcopyrite, cuprite, tenorite, and bornite, from which it is mined.

Jewelry and coins are made from copper alloys. To make bronze, it is mixed with tin. It is also used to make brass when it is mixed with zinc. Copper is a good conductor of electricity, so it is often used in electronic devices’ cables, wires, and circuit boards. It is also very good at transferring heat, so it is used in heaters and coolers as a heat transfer metal.

The melting point of bronze ranges from 850°C to 1050°C (1562°F to 1922°F), depending on the composition of the alloy mixture. The density of bronze is typically between 8.5 g/cm³ to 9.0 g/cm³ (0.307 lb/in³ to 0.326 lb/in³), depending on the specific alloy as well.

Why is bronze better than copper?

Normally, bronze is better and more durable than copper, as it is produced by alloying from copper.

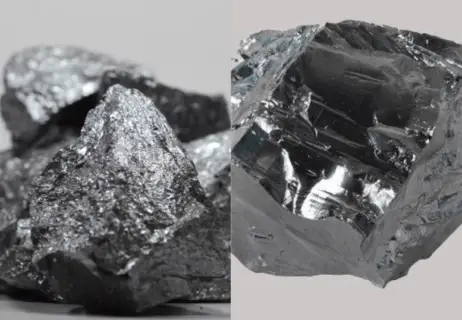

Zinc

From ancient times, zinc has been well known for its blue-white color. Zinc is widely available, but to create durable items, it must be combined with other substances. These mixtures are roasted to produce zinc oxide.

After copper and aluminum, zinc is the third most important metal. It is easily molded and shaped around 150°C but begins to degrade at roughly 210°C. Zinc is a fantastic coating material because of its resistance to corrosion. Autos, businesses, TV displays, and fluorescent lights are all protected by zinc.

Zinc is a major material in many industries due to its flexibility and resistance to corrosion.

At 419.53°C (787.15°F), zinc melts and has a density of 7.14 g/cm3 (0.258 lb/in3).

Silicon

In addition to sealing and insulating surfaces, silicone is a versatile substance that may also be used to join other materials. It is reasonably simple to make, and highly resistant to chemicals and harsh temperatures.

It’s crucial to be sure silicone is suited for the activity at hand before utilizing it since overuse might have unfavorable effects. Several sectors, including those in the automotive, building, energy, electronics, chemicals, coatings, textiles, personal care, and more, utilize silicone extensively.

Overall, silicone is a widely marketed substance with a number of advantages that are used in several commonplace items. It is an important material in many sectors due to its adaptability and distinctive qualities.

Silicone has a melting point of approximately 932°F (500°C) and a density of 1.11 g/cm³ (0.040 lb/in³).

Lead

Rather than naturally occurring, lead is an old metal that is generally found in conjunction with other minerals. Lead is pliable and simple to deal with even though it is not as robust as some other metals. It is often combined with other metals to produce different compounds and alloys, which boost its strength.

Lead is a poor conductor of electricity while being resistant to corrosion. Nonetheless, it may be used to make electrical fuses by combining it with tin. Lead is mostly utilized as paint in commercial settings, but it also serves as a radiation shield in nuclear power plants. Due to its high density, lead is also used to reduce noise.

Overall, lead is a desirable element for a range of applications, including the electrical and nuclear sectors as well as for noise reduction, thanks to its special qualities.

Lead has a melting point of 327.5°C (621.5°F), and a density of 0.410 lb/in3 (11.34 g/cm3). Needs to be mixed to increase its strength during the melting process.

Tin

Tinplate is a lightweight material composed of thin sheets of iron coated with tin, which has a melting point of 231.9°C (449.4°F) and a density of 7.31 g/cm3 (0.264 lb/in3).

It’s widely used in the packaging business to make containers that are simple to make, fill, and seal. Tinplate containers are eco-friendly and may be recycled many times.

They assist to protect the quality of food and beverages by keeping out light, air, and water, therefore extending the product’s shelf life.

Overall, tinplate is a fantastic material for producing lightweight, robust, and ecologically friendly containers that aid in the preservation of packed items’ quality.

Cobalt

I find cobalt to be a fascinating metal with diverse applications. Its uses include the production of blue paint, strong magnets that outperform iron and nickel, and batteries for a wide range of devices. Cobalt’s applications even extend to cancer treatment, where radioactive cobalt is used.

Rare ores, as well as deep-sea shells and nodules, are also a rich source of cobalt. Because of its high strength and wear resistance, it is commonly used in CNC cutting tool manufacturing.

Overall, the broad range of uses for cobalt makes it an essential component in various industries, and I am always impressed by its many applications.

Nickel

Nickel is a naturally occurring metal that is commonly found in the earth’s crust alongside another metal called cobalt. It can be shaped and molded using both hot and cold techniques, making it a versatile material in various industries.

One of its primary uses is in making stainless steel, which is used in many applications due to its strength and resistance to rust. Also, nickel is off in creating pipes, rods, armor, and everyday items like coins, surgical instruments, and lab equipment.

Cold Drawn Metals

Cold drawing is a chipless method of shaping that involves putting sections of hot-rolled steel through a smaller mold to reduce the size of the cross-section and increase the length of the material. This is done to get a smoother surface quality.

Classically, hot-rolled products are made to their final sizes through machining, which also makes sure that the surface is very smooth. But the costs of labor and materials are going up. With the cold drawing process, hot-rolled products can be brought to tighter tolerances and have better surface quality. By cold deforming the product, the material’s hardness and mechanical properties can be made to improve. You don’t have to heat treat the surface to get the hardness you want.

However, it may cause problems with the structure of the material because it gets in the way. Because of this, surface crack control must be used after cold drawing. Hot-rolled bars are pulled out of a die and ground or peeled to make cold-finished bars. Cold-finished steel bars can be put into three main groups based on how they are made.

Sticks that are peeled, ground, and polished

Bars that were cold drawn, ground, and polished

Peeled and shiny sticks

Cold Drawn bars are the most common way to do this.

Hot Rolled Metals

Hot rolling is a high-temperature metal shaping procedure that makes handling simpler. Hot-rolled steel is often more cost-effective than cold-rolled steel owing to its quick production time.

Manufacturers start with a heated billet that is flattened into a roll and then run through rollers to acquire its ultimate size. This technique is often utilized for construction projects and railway rails. As an engineer, I appreciate the process’s efficiency and cost savings.

Tungsten

Tungsten is a material that’s really good for making a strong metal. This metal is mainly used for making steel and iron combined metals. To make the metal, we can mix tungsten with coke or anthracite in an electric furnace.

It was discovered by a scientist named Carl Wilhelm Scheele, and another scientist named Torbeen Bergman improved on it by doing lab experiments. This metal is really tough and can handle high heat really well, It also has a white color and can resist acid for a really long time.

We use tungsten to make things like ships, planes, and trains, and also to create cutters that cut really quickly.

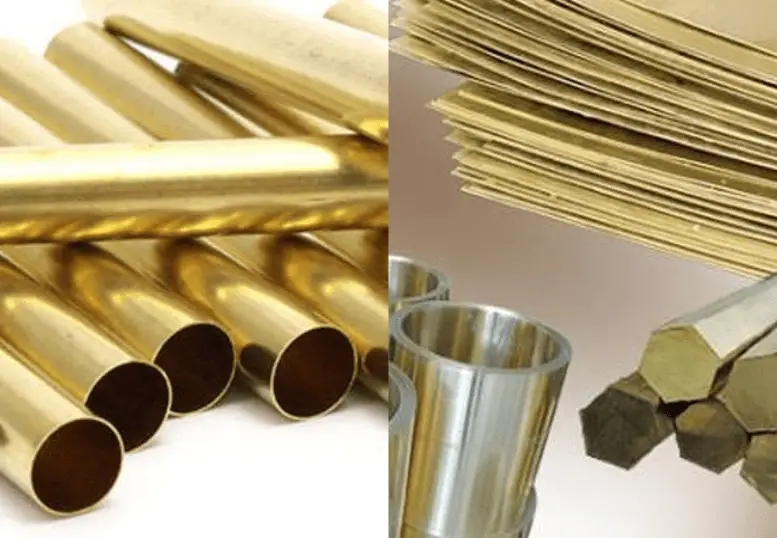

Brass

Brass is a versatile yellow metal made by adding zinc to copper. Brass contains zinc, tin, nickel, manganese, iron, aluminum, antimony, and phosphorus. Brass is robust and simple to deal with. Copper determines its malleability. Bronze, a copper-tin alloy, is brass with manganese.

Aluminum brass is corrosion-resistant. Zinc lightens red copper. Brass becomes yellow as zinc content increases. Brass’s hue indicates zinc content. Tin-containing brass doesn’t degrade in saltwater like other metals while lead-containing brass is simpler to manipulate. saltwater like other metals do, and brass with lead is easier to work with.

Helpful Links

Learn how American steel is made. This website provides nice explanations and animations for learning the manufacturing process.

Internationally learn about aluminum. This website keeps the heartbeat of the aluminum world.

This website has a philosophy through the usage of Titanium.

Summary

We introduced you to some popular engineering metals like; Iron, aluminum, copper, stainless steel, titanium, bronze, zinc, silicon, lead, tin, cobalt, nickel, tungsten, and brass.

A table with key attributes including density, melting point, pricing, and machining and cutting suggestions is supplied with each metal’s description. This information may assist engineers and manufacturers choose the proper metal and improving their machining process.

It is recommended to study the table attentively to fully understand the machining properties of each metal, as well as to identify the ISO material symbols and grouping of related materials. By doing so, one can gain a better understanding of how to work with each metal and achieve the desired results.

In addition to the written article, a video version is also available for those who prefer a visual presentation. This video can provide a clearer understanding of the properties and characteristics of each metal, as well as the machining process.

Overall, this article serves as a comprehensive guide to popular metals used in engineering and CNC machining, providing valuable insights and information that can help individuals and companies make informed decisions when choosing a metal for their application.