CNC machines are capable of machining every shape in our modern industry. Automotive, Medical, Aircraft, and Space technologies all use superior machining advantages of CNC machining. In this blog post, we will deep dive into the different types of CNC machines and their sub-types. Each CNC machine has a unique purpose.

Also please check this article if you general information about understanding common types of CNC machines in the procurement process.

- 1. CNC Milling Machines And Types

- 2. CNC Lathes

- 3. CNC Routers

- 4. CNC Plasma Cutters

- 5. CNC Grinders

- 6. CNC Drilling Machines

- 7. CNC Laser Cutters

- 8. CNC Electrical Discharge Machines (EDM)

- 9. CNC Punch Presses

- 10. CNC Water Jet Cutters

- 11. 3D Printers

- 12. CNC Wire Bending Machines

- 13. CNC Wood Working Machines

- 14. CNC Glass Cutter Machines

- 15. CNC Sheetmetal Bending Machine

- 16. CNC Key Cutting Machines

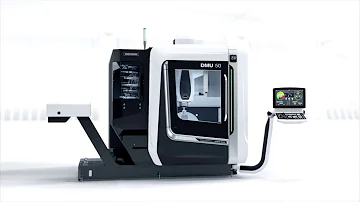

1. CNC Milling Machines And Types

This is one of the most famous CNC machine types. You can easily hear and see it in almost every CNC job shop. It is designed for cutting and shaping prismatic parts with a rotating carbide, HSS cutter. Often more capable milling CNC machines are called machining centers.

a. Vertical Machining Center – VMC

On vertical machines cutting tools are operated vertically. This is the common type of CNC machine that you can see almost in every CNC job shop. This machine works often with 3 axes (x,y,z). However, it is very common that you can put a rotary table for your 4th and 5th axis needs.

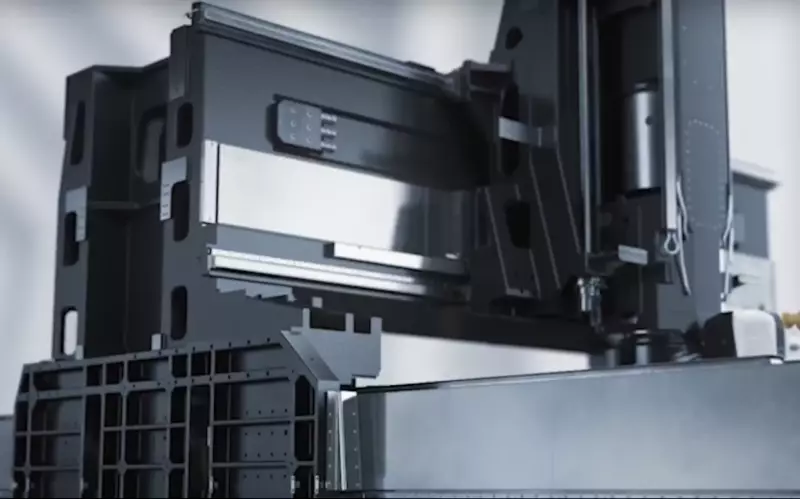

b. Horizontal Machining Center – HMC

In these machines, the spindle axis is horizontally oriented. With this type of CNC machine, you can machine extensive parts. Extendable spindles and palette changers give this kind of machine a cutting-edge competitive advantage. when you need to machine thousands of parts this kind of CNC machine way to go. It operated with 3 axes.

c. 5-Axis Milling Machines

As the name suggests, these machines can operate along five axes. X, Y, and Z axes (which are the 3 basic axes that are a part of all types of CNC machines) and two additional rotary axes. More complex geometries can be machined on one setup. Because of the reduced part setup, you can quote the parts cheaper to your customers and get more clients. These machines give a very competitive edge in getting customers.

2. CNC Lathes

These machines rotate a workpiece on a spindle to perform machining operations such as cutting, tapping, threading knurling, and drilling. This is one of the oldest machining styles of round materials.

a. 2-Axis Lathes

This type of CNC lathe exactly matches with conventional lathes. A basic CNC lathe with 2 axes (X and Z), where the cutting tool moves in two different directions. The X-axis controls the diameter of the workpiece(part to machine) and the Z-axis controls the depth of features on the part. It’s primarily used for machining cylindrical parts. This machine also has a very good turret tool magazine and has zeroing prob for two axes.

b. Multi-Axis CNC Lathes (Mill-Turns)

These lathes have more than two axes (X, Y, Z, C, and B) and can perform a wide range of operations like milling, drilling, and turning simultaneously, These machines can be classified as CNC lathes because of their chuck-spindle-turret structure. They are used for complex machining tasks. Also, they are called as Mill-Turn. Some mill-turns have a steady-rest function and can machine multiple features simultaneously.

c. Swiss-Style CNC Lathes

You can hear them called Swiss screw machines too, these CNC lathes are designed to be extremely proficient for the manufacturing of small parts and also for long, slender parts which would deflect or vibrate, and chatter when turning on a traditional CNC lathe. These machines are derived from conventional Swiss-turning machines. It is perfect for long-run part orders but at the same time not a good fit for small orders due to the complex setup requirement. When setup correctly thousands of parts can be machined unmanned. From using the experience I can tell there are a lot of things to consider when you set up this machine.

d. Vertical Lathes

The spindle and chuck are vertically oriented in these lathes, and the workpiece is held vertically. This is particularly useful for turning heavy circular workpieces. Because of the heavy weight of the part, it would be very hard and risky to hold horizontally. Basically, it would come out of Chuck. Vertical CNC lathes solve this problem by holding the part vertically so the chuck will be placed vertically too.

3. CNC Routers

CNC Routers are one of the most commonly used types of CNC machines. They are designed to cut soft materials like wood, and plastics. Another key difference between CNC Routers is they have a large bridge, bed-style structure which is good for handling large sheets up to 3m x 2m in size. They tend to be cheaper than other CNC machines.

a. Standard 3D Routers

Standard 3D Routers are the most common type of CNC router, it can be desktop style or a large bed, bridge style. Mostly used for carpenters, prototypes, and hobbyists.

b. Multi-functional 5-Axis Routers

5-Axis routers are designed to machine soft complex parts like wood and plastic. Also, they have some features for automatic side machining which can be useful for cabinet makers.

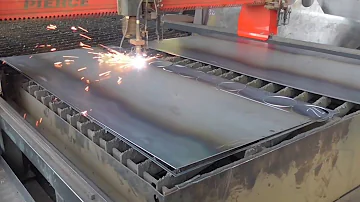

4. CNC Plasma Cutters

CNC Plasma Cutters cut through electrically conductive materials by using an accelerated jet of hot plasma. Generally preferred for cutting the rough outer profile of parts from thick steel.

5. CNC Grinders

CNC Grinders use a rotating grinding wheel to remove material from metal. They are used for tasks like tool sharpening, and cut-off applications. These days CNC grinders can be used for directly machining parts on a grinder without a pre-material removal operation.

6. CNC Drilling Machines

CNC Drilling Machines are used for creating holes in the workpiece. They can perform simple or complex drilling operations. They are called CNC drilling machines but also they can drill and tap holes very fast.CNC drilling machines are designed to change tools in a very short time, so tool-to-part-time is very short. In this way, thousands of holes can be drilled and tapped efficiently.

7. CNC Laser Cutters

Laser technology is in use everywhere in the part machining industry. Laser cutters was one of the early application of laser beams applied industrially. With laser cutters, we can have precise cuts which we cannot have with plasma cutter machines. The laser beam also can cut plastics and a wide range of metals so it has a wide range of application areas.

8. CNC Electrical Discharge Machines (EDM)

a. EDM Carbon Electrode

EDM CNC machines are magical machines that cut the hardest metals like butter. You need to machine a carbon tool which is a concave shape, so when you pluncge with this tool to metals the spark between the carbon tool (electrode) and metal workpiece discharges some material. Don’t miss the point that this tool never touches the workpiece, the electric current touches the parts in the shape of the electrode carbon tool. It is hard to believe but by thousands of retreats, this machine can give very complex shapes to the workpieces. Commonly used by mold and tool makers.

b. EDM Wire Cutting

Wire-cutting EDM works the same as the Carbon electrode. But this type cuts the part by wire. The electrical spark around the wire discharges material from the workpieces. Manipulating wire holders separately you can cut draft angled side walls precisely. Cutting sharp corners is very easy with this type of CNC machine. Also, you will be shocked when you see how this machine can renew and reload wire automatically while cutting.

9. CNC Punch Presses

Cnc Punch Presses is a type of CNC machine that uses cutting and shaping punch tools to produce parts. It cuts sheetmetals by thousands of punch hits by following a toolpath. Also shaping tools can give concave shapes on sheetmetals.These machines are a competitor of the other sheet metal cutting technologies like Laser cutting, and plasma cutting.

10. CNC Water Jet Cutters

CNC Water Jet Cutters use high-pressured water with small abrasive particles in it. When this machine throughs pressured water those small abrasive particles remove material from the metal sheets. This method is very good for cutting thick hard materials.

11. 3D Printers

3D printers these days are very famous. Modern 3D printers can print colorful plastic parts. Lastly, developments show that you can print metal parts with specialized 3D printers.

12. CNC Wire Bending Machines

Wire Bending CNC Machines can bend very complex wire shapes reliably and with high precision. Some machines even can produce springs from the wires.

13. CNC Wood Working Machines

CNC Wood Working Machines work very similar to CNC Routers, however, wood is a dusty material so woodworking CNC machines come with a dust collector and stronger vacuum pump to suck wood sheets through an MDF sheet used as a table.

14. CNC Glass Cutter Machines

CNC Glass Cutter Machines have a similar structure to routers however they come with a special table that can hold the glass properly. Also, they use a special glass-cutting tool to cut glass.

15. CNC Sheetmetal Bending Machine

A CNC metal bending Machine is a bending machine that can bend any kind of flexible metal at a given angle. Sheet metal parts generally come from the laser cut or a punch cut machine. Sheet metal bending machines can calculate spring-back values and can give automatic allowance to catch the correct angle.

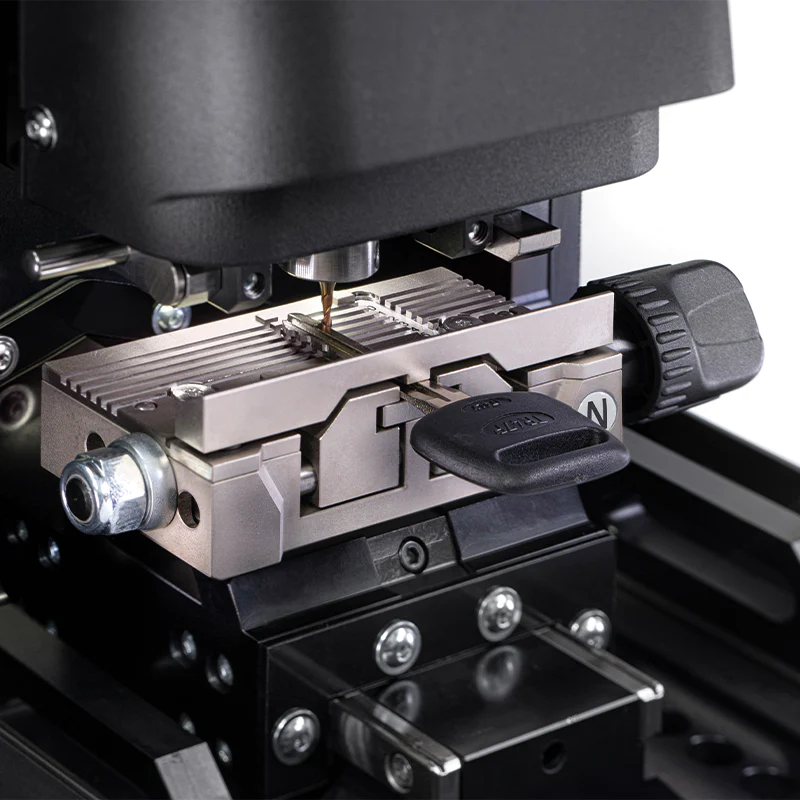

16. CNC Key Cutting Machines

This is a small CNC machine type designed for cutting complex key profiles for locksmiths. Even those machines come with pre-programmed and there is no need for a whole trained person to use it. Locksmiths can use it very easily without learning the CNC machining profession.