- 1. How Do I Choose The Right Tap?

- 2. Hand Taps: The Traditional Choice

- 3.Power-CNC Machine Taps: The Versatile Option

- 4. Interrupted Thread Taper Pipe Taps

- 5. Pipe Taps: The Plumbing Pro

- 6. Punch Taps: The Innovation in Tapping

- 7. Cold Forming or Roll Taps: The Chipless Choice

- 8. Extended Taps: The Deep Hole Solution

- 9. Thread Milling: The CNC Specialist Alternative

- 10. Decoding Tap Markings: A Simple Guide to Understanding Standard Tap Labels

- 11. The Tap in Action: Real-World Scenarios

- 12. Avoiding Tap Breakage: Essential Tips for Safe and Effective Tapping

- 13. Mechutopia`s bonus tables for threads, pitches, and tap drill sizes

- 14. Summary

In the world of making things with machines, the tap is a tool that people often forget about. But, this simple tool is very important because it helps us make the inside of holes smooth and accurate. Today, we’re going to talk about the tap, look at 11 different kinds, and give you some tips to help you pick the best tap for your project.

Check this for Metric Standard Tap and Drill Sizes With Pitch Table

Check this comprehensive guide for tapping with a CNC machine.

[email_subscription]

1. How Do I Choose The Right Tap?

Selecting the right tap isn’t just about understanding the different types. You also need to consider factors like the diameter of the screw to be drilled, the type of thread profile, your project budget, and the number of tapped holes required. By taking these factors into account, you can ensure that you choose the right tap for the job.

2. Hand Taps: The Traditional Choice

Hand taps are the most common type of tap and are typically used for manual tapping. They’re ideal for materials that produce easily breakable chips. Hand taps come in sets of three: taper, plug, and bottoming, each serving a unique purpose in the tapping process.

a. Taper Tap

This is the first tap and it puts almost half of the full depth of the thread. Because entrance threads are tapered, it is easy to rotate and tap on a good alignment.

b. Plug Tap

The second Taps are for removing more materials in the middle depth of the hole.

c. Bottom Tap

Lastly, the third Tap removes the whole material until the bottom of the hole and gives the final Tap`s thread shape.

[email_subscription]

3.Power-CNC Machine Taps: The Versatile Option

Power-CNC machine taps are a versatile choice, suitable for both manual and CNC machine use. They’re designed to withstand the high-speed operation of CNC machines, making them a popular choice for high-volume production environments.

4. Interrupted Thread Taper Pipe Taps

Interrupted Thread Taper Pipe Taps are specialized tools designed for creating internal threads in pipes and pipe fittings. These taps are characterized by their unique design, which features an alternating pattern of teeth and gaps. This “interrupted” thread design offers several advantages:

- Improved Chip Flow: The gaps in the thread pattern provide space for chips to flow away from the cutting edge of the tap. This helps to prevent chip buildup, which can cause the tap to jam or break.

- Reduced Friction: The interrupted thread design reduces the surface area of the tap that comes into contact with the workpiece. This results in less friction, which can make the tapping process smoother and more efficient.

- Increased Speed: Because they cut fewer threads per revolution, interrupted thread taps can often complete the tapping process more quickly than standard taps.

- Longer Tool Life: The reduced friction and improved chip flow can help to prolong the life of the tap by reducing wear and tear.

5. Pipe Taps: The Plumbing Pro

As the name suggests, pipe taps are used to create threads in pipes and pipe fittings. They’re designed to handle the unique challenges of threading pipe material, making them an essential tool for plumbers and pipefitters.

There are two main types of pipe taps:

- Tapered Pipe Taps: These taps have a slight taper to their threads, which helps to ensure a tight seal when a threaded pipe or fitting is screwed into the hole. They’re used for creating threads in fittings for water, gas, and other fluid systems.

- Straight Pipe Taps: These taps have straight threads and are typically used for mechanical joints, such as those found in automotive or industrial applications.

The benefits of pipe taps include:

- Versatility: Pipe taps can be used with a variety of materials, including metal, plastic, and more.

- Precision: Pipe taps create precise threads that ensure a secure fit and seal when a threaded pipe or fitting is screwed into the hole.

- Durability: The threads created by pipe taps are typically strong and durable, making them suitable for high-pressure systems.

Overview of how they work:

- Application: The pipe tap is applied to a pre-drilled hole in a pipe or pipe fitting.

- Cutting: As the tap is rotated, it cuts threads into the inner surface of the hole.

- Completion: Once the tap has been fully inserted and then removed, the threaded hole is ready to accept a threaded pipe or fitting.

6. Punch Taps: The Innovation in Tapping

Punch taps are a relatively new innovation in the world of tapping, offering a unique approach to thread creation. Developed through a collaboration between Emuge Franken, a German tool manufacturer, and Audi, the automotive company, punch taps are designed to create internal thread forms at a significantly faster rate than traditional taps.

Here’s how they work:

- Penetration: The punch tap initially penetrates the workpiece with a minimal helical movement, similar to the way a drill works. This is much faster than the traditional spiral movement of a standard tap.

- Forming: Once the punch tap has reached the required depth, it expands its three lobes (or cutting edges) to form the thread. This is done by moving the tap laterally, which is a much quicker movement than the traditional rotation.

- Retraction: After the thread has been formed, the lobes retract, and the tap is extracted from the hole along the same helical path it entered.

The benefits of punch taps include:

- Speed: Punch taps can create threads up to three times faster than traditional taps, making them ideal for high-volume production environments.

- Efficiency: Because punch taps form threads by deformation rather than cutting, they don’t produce chips. This eliminates the need for chip evacuation and reduces the risk of tap breakage due to chip clogging.

- Durability: The threads created by punch taps are typically stronger and more durable than cut threads, as the material is work-hardened during the forming process.

However, it’s important to note that punch taps require specialized CNC machines capable of performing the unique movements required by the punch-tapping process. They’re also best suited to materials with good ductility, such as aluminum.

[email_subscription]

7. Cold Forming or Roll Taps: The Chipless Choice

Cold forming or roll taps don’t cut material like traditional taps. Instead, they shape the material by plastic deformation, creating a thread without producing chips. This makes them a great choice for materials that produce difficult-to-manage chips.

Here’s how it works:

- Penetration: The roll tap, which has a lobe design rather than cutting edges, is applied to a pre-drilled hole in the workpiece.

- Forming: As the tap is rotated, it applies high pressure to the material, causing it to flow into the lobes and form the threads.

- Completion: Once the tap has been fully inserted and then removed, the thread is complete.

The benefits of cold forming or roll taps include:

- No Chips: Since the process doesn’t involve cutting, no chips are produced. This eliminates the need for chip evacuation and reduces the risk of tap breakage due to chip clogging.

- Stronger Threads: The threads created by roll taps are typically stronger than cut threads. This is because the material is work-hardened during the forming process, which can improve its strength and wear resistance.

- Efficiency: Roll tapping can be faster than traditional tapping, especially in materials that are well-suited to the process, such as aluminum and other ductile materials.

Let me notice you, it’s important to note that not all materials are suitable for cold forming. Brittle materials, such as cast iron, may crack or break under the high pressure applied during the process. Therefore, it’s crucial to consider the material properties when choosing a tapping method.

Table of Advantages & Disadvantages of Cold Form Tapping

| COLD FORM TAPPING | |

|---|---|

| ADVANTAGES | DISADVANTAGES |

| Performs high-speed forming. | It requires special size drills which is different than standard sizes. |

| It is almost impossible to break the tap. | Requires a high oil-containing coolant to facilitate thread shaping. |

| It takes long time for the tap to wear down. | Taps are more expensive than standard taps. |

8. Extended Taps: The Deep Hole Solution

These taps are very risky to use because the moment on the handle can break the extended tap easily. The handle shoulder of the extension tap is long. With this long shoulder, it’s easy to get too deep holes that a regular tap can’t reach.

9. Thread Milling: The CNC Specialist Alternative

Thread milling is a specialized process used by CNC machines to create threads. Unlike traditional tapping, thread milling uses a helical interpolation motion to carve out the thread profile, offering high precision and flexibility.

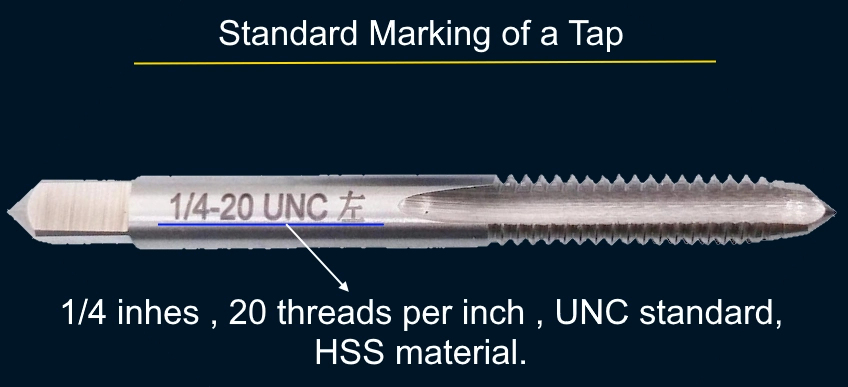

10. Decoding Tap Markings: A Simple Guide to Understanding Standard Tap Labels

- Tap Type: The first part of the marking usually indicates the type of tap. For example, “H” for hand tap, “S” for spinal tap, etc.

- Thread Size: The next part of the marking indicates the thread size. This is usually a number that represents the diameter of the thread. For example, “1/4” means the thread is a quarter of an inch in diameter.

- Thread Pitch: After the thread size, you’ll see another number that represents the thread pitch. This is the distance between each thread. For example, “20” means there are 20 threads per inch.

- Material and Coating: The marking may also include letters that represent the material the tap is made from and any coating it has. For example, “HSS” stands for high-speed steel, a common material for taps, and “TiN” stands for titanium nitride, a common coating that increases the tap’s hardness and lifespan.

- Standard: Finally, the marking may include a reference to the standard the tap conforms to. For example, “UNC” stands for Unified National Coarse, a standard for the shape and angle of the threads.

So, a complete tap marking might look something like this: “H 1/4 20 HSS TiN UNC”. This would mean it’s a hand tap, with a thread size of 1/4 inch and 20 threads per inch, made from high-speed steel with a titanium nitride coating, and it conforms to the Unified National Coarse standard.

11. The Tap in Action: Real-World Scenarios

Let’s bring these taps to life with some real-world scenarios. Imagine you’re working on a custom car part that requires a deep threaded hole.

[email_subscription]

An extended tap would be your tool of choice. Or perhaps you’re machining a part for a high-volume production run. A power-CNC machine tap would be ideal, offering the speed and precision you need.

Taps may be small, but they play a big role in machining. They’re the unsung heroes, working behind the scenes to ensure that your threading operations are efficient, precise, and high-quality. So next time you reach for a tap, take a moment to appreciate this humble tool. It’s not just a tool, it’s a key to unlocking the full potential of your machining operations.

12. Avoiding Tap Breakage: Essential Tips for Safe and Effective Tapping

Breaking a tap can be a frustrating and costly mistake. But with the right techniques and precautions, you can minimize the risk of tap breakage and ensure a smooth and successful tapping process. Here are some essential tips:

- Use the Right Tap for the Material: Different materials require different types of taps. For example, softer materials like aluminum are well-suited to spiral flute taps, while harder materials like stainless steel may require a straight flute tap. Using the wrong type of tap for the material can increase the risk of breakage.

- Ensure Proper Alignment: Misalignment can cause the tap to break under the strain of cutting threads at an angle. Always ensure the tap is perfectly aligned with the hole before you start tapping.

- Apply Appropriate Pressure: Applying too much pressure can cause the tap to break. It’s important to apply steady, even pressure and to avoid forcing the tap into the material.

- Use Cutting Fluid: Cutting fluid helps to lubricate the tap, reducing friction and heat, and making the tapping process smoother. This can significantly reduce the risk of tap breakage.

- Clear Chips Regularly: As the tap cuts the threads, it produces chips (small pieces of material). If these chips aren’t cleared away, they can clog the tap and cause it to break. Regularly reverse the tap to clear away chips.

- Check Tap Condition: Always check the condition of your tap before using it. A worn or damaged tap is much more likely to break. If the tap is dull or has damaged threads, it’s time to replace it.

Remember, safety should always be your top priority when tapping. Always wear appropriate safety gear, including safety glasses, and follow all safety guidelines for your tools and workspace.

13. Mechutopia`s bonus tables for threads, pitches, and tap drill sizes

This list includes short names for threads and standards.

ACME 60° STUB 60° Stub thread form

ACME STUB Stub Acme thread form

ACME-C Acme Thread-Centralizing

ACME-G Acme Thread-General Purpose

AMO American Standard Microscope Objective Thread

ANPT Aeronautical National Form Taper Pipe Thread

(Ground thread tap marked NPT)

AWWA American Water Works Association

BA British Association Standard Thread

BSF British Standard Fine Thread Series

BSPP British Standard Pipe (Parallel) Thread

BSPT British Standard Taper Pipe Thread

BSW British Standard Whitworth Coarse Thread Series

MM ISO Metric thread form

N American National 8, 12, and 16 Thread Series (8N, 12N, 16N)

N BUTT American Buttress Screw Thread

NC American National Coarse Thread Series

NEF American National Extra Fine Thread Series

NF American National Fine Thread Series

NGO National Gas Outlet Thread

NGT National Gas Taper Thread

NH American National Hose Coupling and Fire Hose Coupling Threads

NPSC American National Standard Straight Pipe Thread in Pipe Couplings (Tap marked NPS)

NPSF Dryseal American National Standard Fuel Internal Straight Pipe Thread

NPSH American National Standard Straight Pipe Thread for Hose Couplings

NPSI Dryseal American National Standard Intermediate Internal Straight Pipe Thread

NPSL American National Standard Straight Pipe Thread for Loose Fitting Mechanical Joints with Locknuts

NPSM American National Standard Straight Pipe Threads for Free-Fitting Mechanical Joints for Fixtures (Tap marked NPS)

NPT American National Standard Taper Pipe Thread

NPTF Dryseal American National Standard Taper Pipe Thread

NPTR American National Standard Taper Pipe Thread for Railing Joints (Tap marked NPT)

NS American National Thread-Special

PDF Dryseal SAE Short Taper Pipe Thread

SGT Special Gas Taper Thread

SPL-PTF Dryseal Special Taper Pipe Thread

STI Special Thread for Helical Coil Wire Screw Thread Inserts

Stub Acme Stub Acme Thread

UN Unified and American thread series

UNC Unified and American Coarse thread series

UNEF Unified and American Extra-Fine thread series

UNF Unified and American Fine thread series

UNJ Unified Thread Series with a 0.15011P to 0.18042P Controlled Root Radius on External Thread only.

UNJC Unified Coarse Thread Series with a 0.15011P to 0.18042P Controlled Root Radius on External Thread only.

UNJF Unified Fine Thread Series with a 0.15011P to 0.18042P Controlled Root Radius on External Thread only.

UNM Unified Miniature Thread Series

UNR Unified Constant Pitch Thread Series with a 0.108P to 0.144P Controlled Root Radius; Ext. thread only.

UNRC Unified Coarse Thread Series with a 0.108P to 0.144P Controlled Root Radius; Ext. thread only.

UNRF Unified Fine Thread Series with a 0.108P to 0.144P Controlled Root Radius; External thread only.

UNS Unified and American threads of selected special diameters and pitches

V A 60 “V” thread with Truncated Crest and Root. The theoretical “V” Form is usually flatted to the user’s specifications.

WHIT British Standard Whitworth Special Thread.

14. Summary

From the traditional hand tap to the innovative punch tap, the world of taps is diverse and fascinating. By understanding the different types of taps and how to choose the right one, you can take your machining skills to the next level. So here’s to the tap – a small tool with a big impact.